BoilerMate Model Numbers

BMA 180 HP-PQFY

BMA 210 HP-PQFY

BMA 240 HP-PQFY

The code of practice for the installation, commissioning & servicing of central heating systems

Building Regulations and Benchmark Commissioning

The Building Regulations (England & Wales) require that the installation of a heating appliance be notified to the relevant Local Authority Building Control Department. From 1st April 2005 this can be achieved via a Competent Person Self Certification Scheme as an option to notifying the Local Authority directly. Similar arrangements will follow for Scotland and will apply in Northern Ireland from 1st January 06.

CORGI operates a Self Certification Scheme for gas heating appliances.

These arrangements represent a change from the situation whereby compliance with the Building Regulations was accepted if the Benchmark Logbook was completed and this was then left on site with the customer).

With the introduction of a self certification scheme, the Benchmark Logbook is being replaced by a similar document in the form of a commissioning check list and a service interval record is included with all gas appliance manuals. However, the relevant Benchmark Logbook is still being included with all Thermal Storage products and unvented cylinders.

Gledhill fully supports the Benchmark aims to improve the standards of installation and commissioning of central heating systems in the UK and to encourage the regular servicing of all central heating systems to ensure safety and efficiency.

Building Regulations require that the heating installation should comply with the manufacturer’s instructions. It is therefore important that the commissioning check list is completed by the competent installer. This check list only applies to installations in dwellings or some related structures.

ISSUE 5: 12-07

| Section | Page |

| Summary Checklist | 3 |

| BOILERMATE HP-DEM | |

| DESIGN | |

| Introduction | 5 |

| Technical Data | 8 |

| System Details | 17 |

| INSTALLATION | |

| Site Requirements | 25 |

| Installation | 26 |

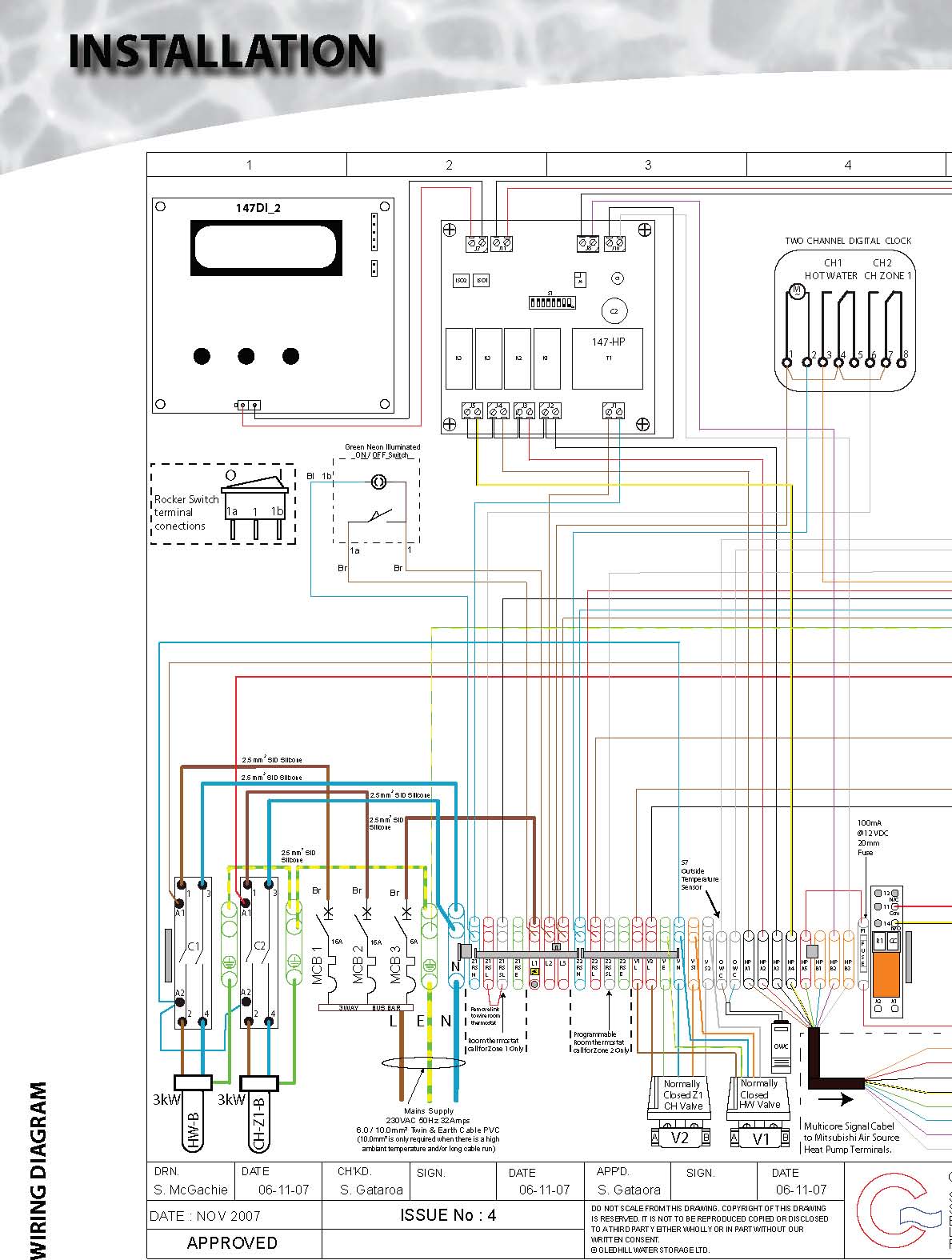

| Wiring Diagrams | 28 |

| Commissioning | 31 |

| SERVICING | |

| Servicing/Maintenance | 33 |

| Changing Components | 33 |

| Short Parts List | 34 |

| Fault Finding | 35 |

| MITSUBISHI ELECTRIC ECODAN | |

| AIR SOURCE HEAT PUMP | |

| Installation Manual | 36 |

BOILERMATE HP-PQFY / MITSUBISHI PQFY HEAT PUMP DETAILS

Electrical / Hydraulic

Connection Layouts 44

BoilerMate HP-PQFY Appliance

Electrical Schematic 46

FERNOX BOILER BUDDY

Installation Manual 48

FERNOX ALPHI-11

Product Data 52

Gledhill Terms & Conditions 54

This product is manufactured under an ISO 9001:2000 Quality System audited by BSI.

Patents Pending.

The Gledhill Group’s first priority is to give a high quality service to our customers.

Quality is built into every Gledhill product and we hope you get satisfactory service from Gledhill.

If not please let us know.

Page 2

differences from other types of heating systems that you will have installed. We suggest you use this checklist as a helpful summary of the main differences from conventional heating systems, but you will also need to understand and comply with all of the technical details contained within this document to ensure a successful installation. For further assistance please contact Gledhill Technical Support Helpline on 08449 310000.

Incoming Water Supply

• As the performance of hot and cold water systems is totally reliant on the incoming mains cold water supply, check that the pressure will be a minimum of 2 bar at times of maximum simultaneous use and that the flow rate is a minimum of 30 litres/minute. (For optimum performance this will need to be 50 litres in larger properties.)

SUMMARY CHECkLIST

Page 4

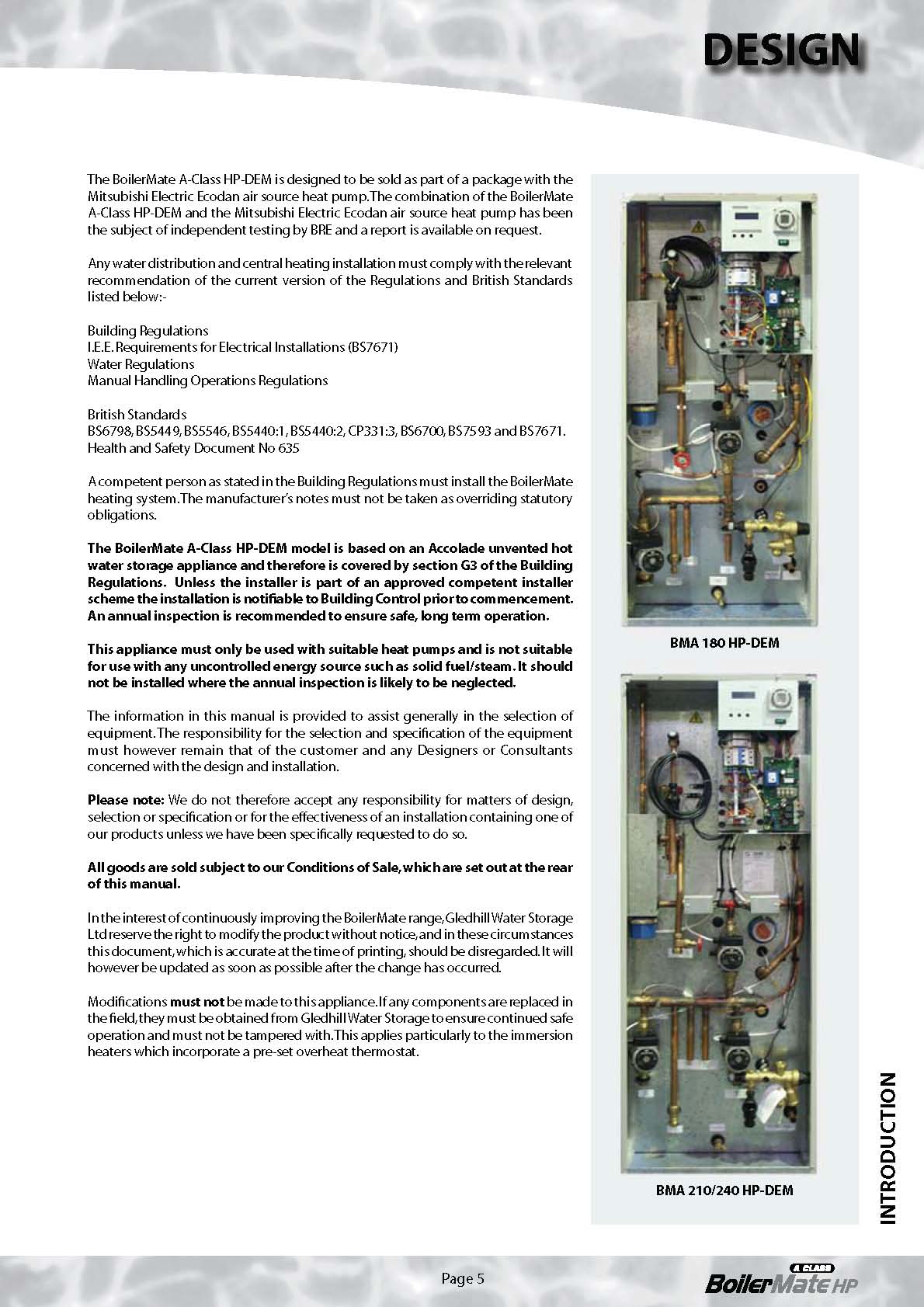

INTRODUCTION

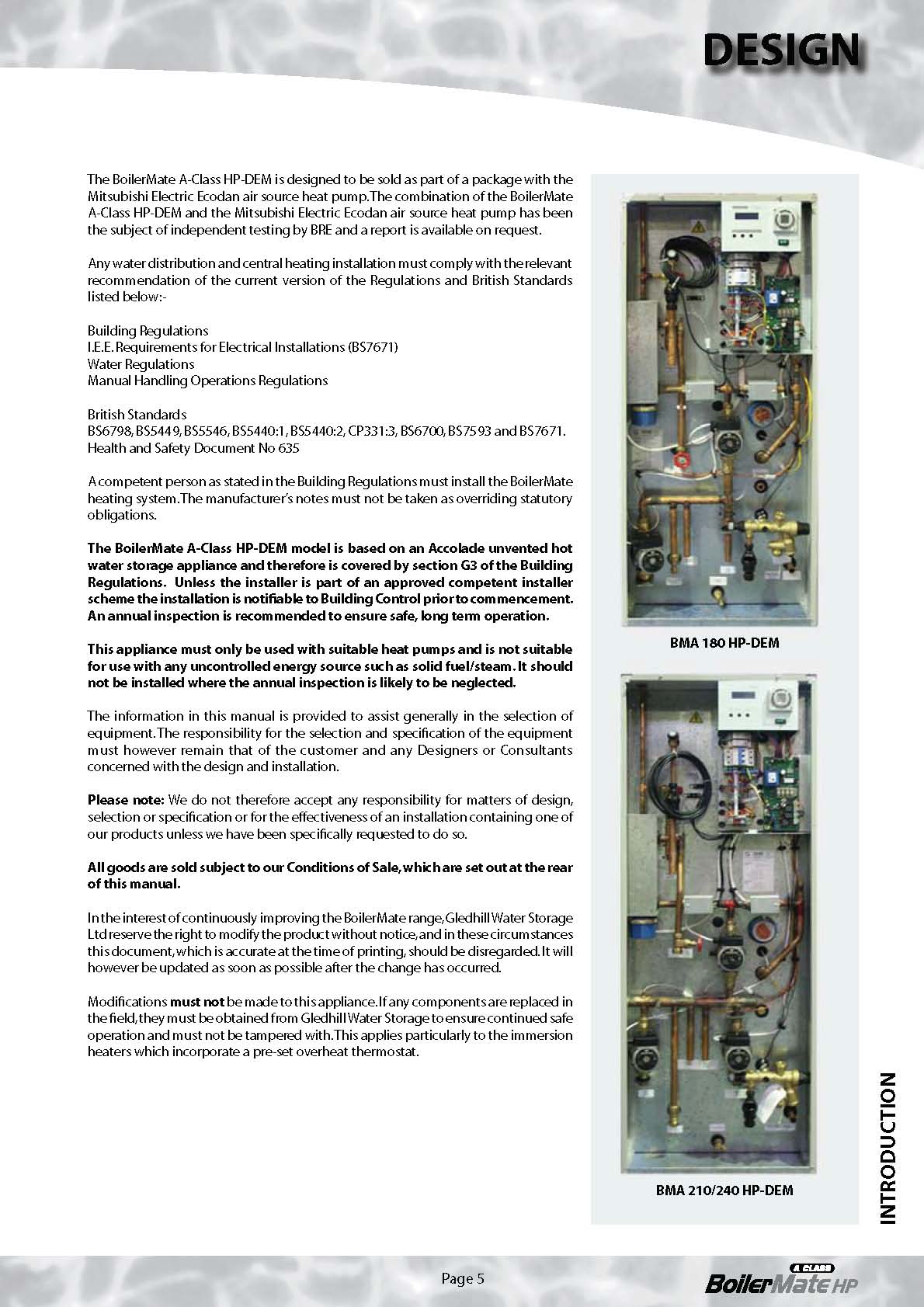

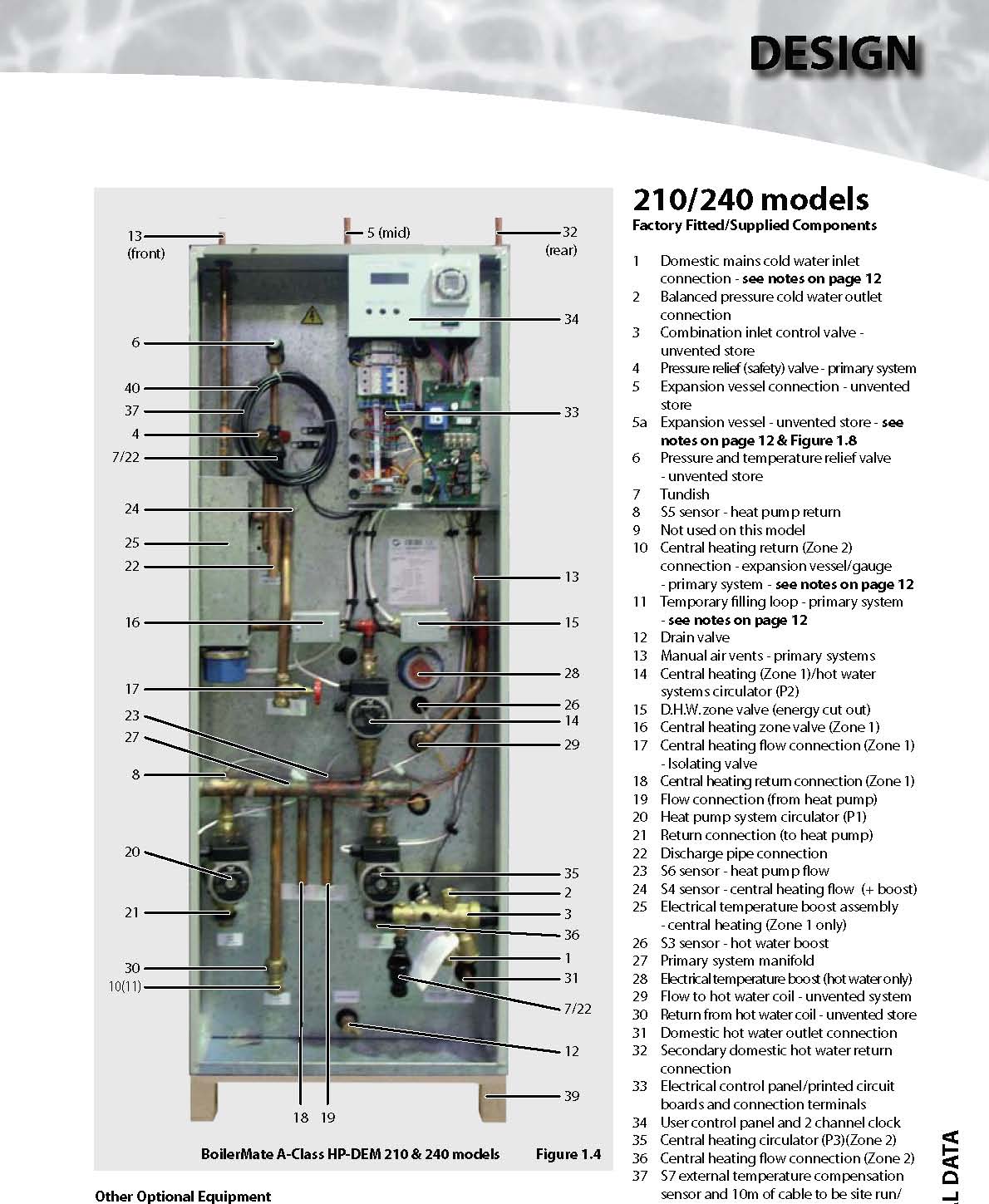

| A BoilerMate A-Class HP-DEM is a floor standing packaged mains pressure unvented | different design temperatures if required. |

| hot water appliance designed for use with the Mitsubishi Electric Ecodan air source | |

| heat pump. All models are factory fitted with all the necessary safety and control | The BoilerMate A-Class HP-DEM is supplied |

| equipment for connecting to the domestic water systems, heat pump and the heating | with an outside temperature compensation |

| system as can be seen from figures 1.1, 1.2, 1.3 and 1.4. | sensor which needs to be mounted externally |

| and wired back to the connection terminals |

| The appliance has been specifically designed to maximise the efficiency of the heat | provided in the appliance (using the 10m of |

| pump and use the energy to provide improved space heating and mains pressure | cable provided). This will then automatically |

| hot water performance. | adjust the operation of both zone 1 and zone 2 |

| heating circuits to take account of the external |

| The built in controls monitor the demands for heat ensuring that the low cost energy | temperature and reduce the running costs. |

| from the heat pump is used whenever possible and top up from the conventional | |

| heat source is only initiated when the flow temperature from the heat pump is not | 8 metres of 8 core signal cable is also provided |

| sufficient to meet the demands. The controls are set to provide hot water priority, ie. | for connection between the BoilerMate A-Class |

| if there is a demand at S3, any heating demands will be suspended until the store | HP-DEM appliance and the heat pump (see |

| temperature reaches the point where S3 is satisfied. | page 30 for details). |

| All models are designed to heat the domestic hot water indirectly up to the maximum | The most economical way of designing the |

| temperature possible with the heat pump and then boost the temperature by means of | heating systems is to utilise the temperature |

| a 3kW immersion heater up to the required set temperature.All models have connections | available from the heat pump itself. For this |

| for a zone 1 circuit where the central heating flow temperature can be boosted by means | reason, underfloor/low temperature radiator |

| of an inline electric heater to the preset design temperature. However, the 210 and 240 | systems should be chosen where possible. In |

| models also have connections for a zone 2 circuit where no temperature boost is provided. | these situations, the electric boost heater can be |

| This enables separate radiator and underfloor heating circuits to be provided,operating at | disabled at the control panel if required. |

Page 6

| Once installed and commissioned, the integration of all the heat pump, domestic | Scale Protection |

| hot water and central heating functions will be automatically controlled by the PCB | |

| built into the BoilerMate A-Class HP-DEM appliance. However, the temperature of the | The Building Regulations L1A: New dwellings/ |

| central heating will need to be controlled by remote room thermostat(s)/thermostatic | L1B:Existing dwellings and the requirements set |

| radiator valves. | out in the Domestic Heating Compliance Guide |

| specify that “where the mains water hardness |

| Details of how to enter this product in SAP are available. Please request a copy of | exceeds 200ppm provision should be made to |

| the latest SAP Data Sheet which covers this and all other Gledhill Water Storage | treat the feed water to water heaters and the hot |

| products. | water circuit of combination boilers to reduce |

| the rate of accumulation of lime scale”. |

| In the event the heat pump fails, both the domestic hot water and central heating | |

| (partial only) can be heated using the built in electric heaters.This manual emergency | To comply with this requirement the hardness |

| heating mode can be selected by pressing the button labelled‘switch’ on the appliance | of the mains water should be checked by the |

| front panel for 5 seconds. Even in this mode the controls will give priority to the hot | installer and if necessary the optional factory |

| water. However, the appliance should only be operated in this mode for the short | fitted in-line scale inhibitor should be specified |

| period of time required for the problem to be resolved. | at the time of order for hardness levels between |

| 200 and 300 ppm (mg/l). |

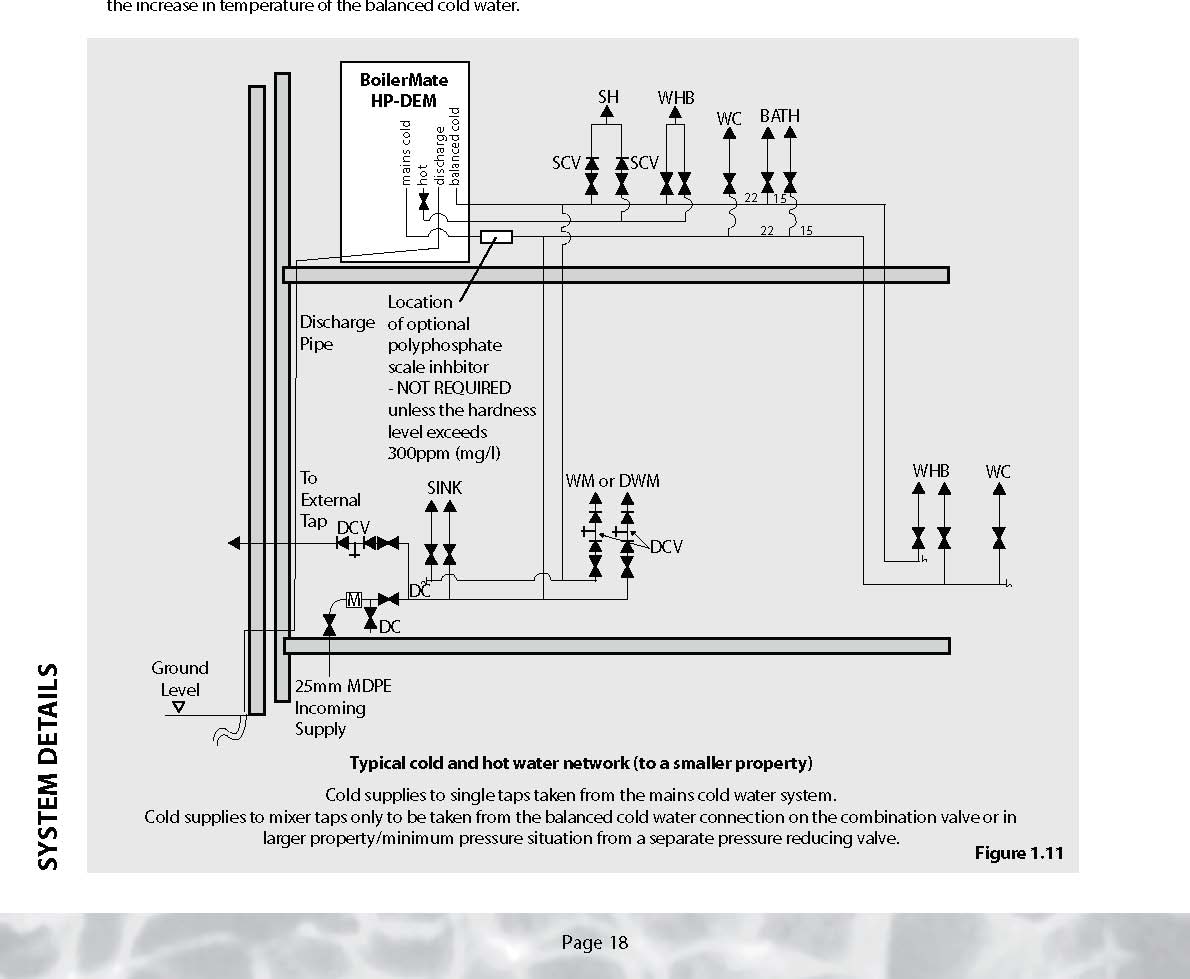

| The BoilerMate A-Class HP-DEM is designed to be sold as part of a package with the | |

| Mitsubishi Electric Ecodan air source heat pump. The combination of the BoilerMate | Where the water is very hard ie 300ppm (mg/l) |

| A-Class HP-DEM and the Mitsubishi Electric Ecodan air source heat pump has been | and above the optional polyphosphate type, |

| the subject of independent testing by BRE and a report is available on request. To | inhibitor should be specified at the time of |

| allow a visual indication of system water quality and to protect the waterways of | order. However, this will need to be fitted by |

| the heat pump from contamination a Fernox Boiler Buddy is provided as part of the | the installer at a suitable point in the cold water |

| package. | supply to the appliance. |

INTRODUCTION

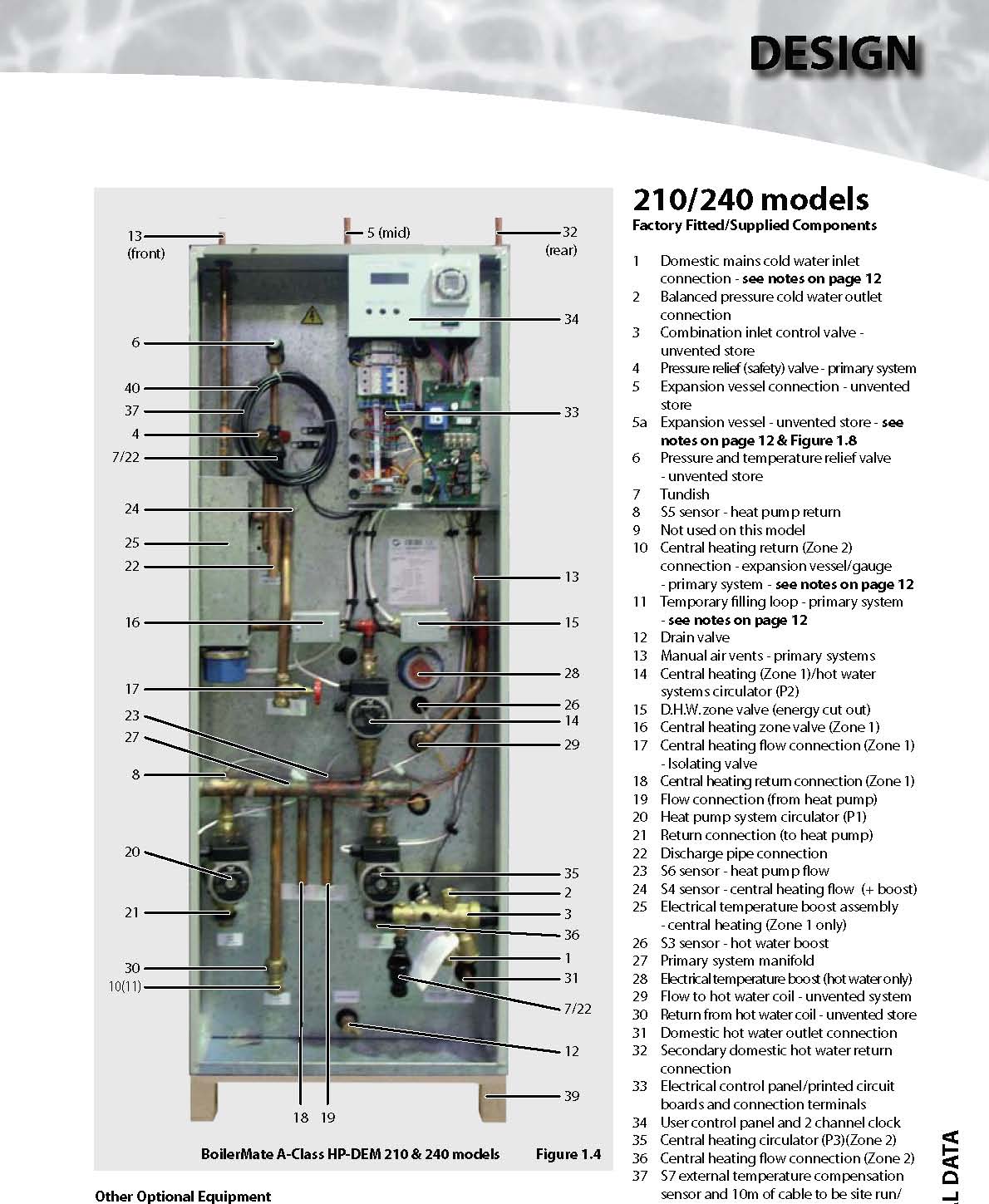

- Hot and cold water manifolds for use with plastic pipework (Set 1 or 2). 37 S7 external temperature compensation

- Electronic scale inhibitor for mains water services with hardness levels above sensor and 10m of cable to be site run/ 200ppm (mg/l) fitted in the appliance. fitted by installer

- Polyphosphate scale and corrosion inhibitor for mains water services with 38 Fernox ‘Boiler Buddy’ in-line filter - see hardness levels above 300ppm (mg/l) for fitting on site by the installer. notes on page 12

sensor and 10m of cable to be site run/ fitted by installer

- Hot and cold water manifolds for use with plastic pipework (Set 1 or 2). 38 Fernox ‘Boiler Buddy’ in-line filter - see

- Electronic scale inhibitor for mains water services with hardness levels above notes on page 12 200ppm (mg/l) fitted in the appliance. 39 100mm high installation base

- Polyphosphate scale and corrosion inhibitor for mains water services with 40 8m 8 core signal cable to be site run/ hardness levels above 300ppm (mg/l) for fitting on site by the installer. connected to Mitsubishi HP by the installer

TECHNICAL DATA

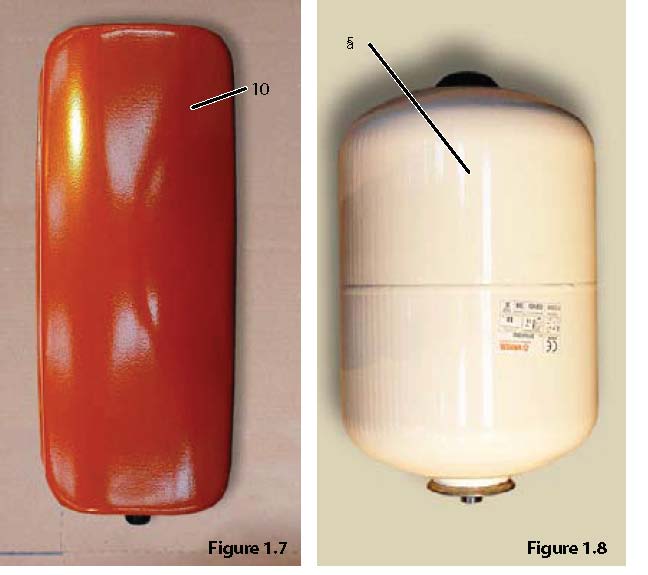

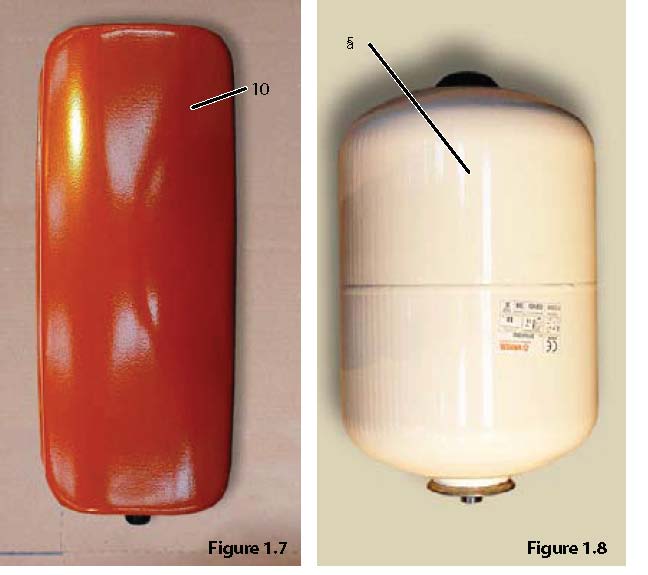

Item 5a is supplied separately with the appliance (see Figure 1.8 and Table 1.1 below for details), complete with a fixing bracket and pipework installation kit.

Items 10 and 11 are available as an optional Primary Sealed System Kit at extra cost. If required, this should be ordered at the same time as the appliance (see Figure 1.7 and Table 1.1 below for details). The expansion vessels are provided with a suitable fixing bracket.

Item 38 is supplied separately with the appliance package for fitting internally in the heat pump return as near as possible to the heat pump, fully in accordance with the manufacturers instructions included later in this manual.

The appliance is available with the option of a factory fitted scale inhibitor, at extra cost. In this case the aerial is fitted on the 22mm cold inlet and the scale inhibitor PCB is fitted in the electrical panel/PCB area.

Primary system expansion vessel Unvented store expansion vessel available as an optional extra at the supplied separately with the appliance time of order as part of the Primary

Sealed System kit

Table 1.1

TECHNICAL DATA

| Expansion Vessels | |

|---|

| Model | Primary Expansion Vessel (Optional Extra) | Unvented Store Expansion Vessel (Supplied) |

|---|

| Capacity (l) | Size (mm) LxWxH | Capacity (l) | Size-each (mm) LxDiam |

| BMA 180 HP-DEM | 12 | 500 x 200 x 160 | 12 | 270 x 270 |

|---|

| BMA 210 HP-DEM | 12 | 500 x 200 x 160 | 12 | 270 x 270 |

|---|

| BMA 240 HP-DEM | 2 x 12 | 500 x 200 x 160 | 18 | 400 x 270 |

|---|

The size of the primary system expansion vessel has been calculated using typical design size should be checked and confirmed as being criteria for the maximum recommended heating load shown in Table 1.2. However, the accurate by the system designer/installer.

| Technical Data |

|---|

| Model | BMA 180 HP-DEM | BMA 210 HP-DEM | BMA 240 HP-DEM |

|---|

| Nominal domestic hot water storage volume (litres) | 145 | 171 | 215 |

|---|

| Overall app. dimensions (mm) | (Height x Width x Depth) | 1370 x 595 x 595 | 1600 x 595 x 595 | 1950 x 595 x 595 |

|---|

| Minimum recommended cupboard dimensions (mm) | (Height x Width x Depth) | 1970 x 700 x 600 (1) | 2200 x 700 x 600 (1) | 2250 x 700 x 700 (1) |

|---|

| Weight (kg) | (Empty / Full) | 87 / 232 | 103 / 274 | 114 / 329 |

|---|

| Unvented store expansion vessel | Type: Varem | 1 Off (2) |

|---|

| Total nominal volume (litres) | 12 | 18 |

| Charge pressure (bar) | 1.5 |

| Heat pump circuit circulating pump P1 | Grundfos UPS 15-50 |

|---|

| System circulating pump P2 (HW and Zone 1 CH) | Grundfos UPS 15-50 |

|---|

| Circulating pump P3 (Zone 2 CH) | –––– | Grundfos UPS 15-50 |

|---|

| HW circuit zone valve - type Honeywell V4043 | 22mm |

|---|

| CH circuit zone valve - type Honeywell V4043 | 22mm |

|---|

| Electrical data | Supply: 230V AC, 50Hz rated at | 6.5kW |

|---|

| Main supply circuit breaker | 32A type B |

| Internal protection: Immersion heaters | 2 x 16A MCBs (Type B) |

| Internal protection: Control circuit | 1 x 6A MCB (Type B) |

| Internal protection: Heat pump L.V. control signal (12VDC signal) | 1 x 100mA 20mm glass cartridge fuse (+ spare) |

| Control & overheat safety thermostat temperature settings | HW boost immersion heater | S1/S2 safety sensors (3) |

|---|

| P & T valve | 900C |

| CH boost immersion heater | Control thermostat(5): 650C, Overheat thermostat(4): 850C |

| Control/relief valve pressure set points | Mains inlet pressure regulator | 1.5 bar |

|---|

| Expansion relief valve (CW) | 3.0 bar |

| Expansion relief valve (CH) | 3.0 bar |

| P & T valve | 4.0 bar |

| Maximum hot water flow rate | 25-35 |

|---|

| Dwelling type | Bedrooms | 3-4 | 3-4 | 3-5 |

|---|

| Bathrooms | 1 | 1 | 2 |

| En-suite | 1 | 2 | 1 |

| Maximum heating load | 13kW |

|---|

| Electrical backup ‘switch’ | 6kW |

|---|

| (1) The sizes shown allow for the unvented store expansion vessel to be fitted above the appliance in the case of the 180 and 210 models, but assume that the optional primary sealed system kit will be fitted elsewhere. The dimensions for the 240 model assume both the unvented store and primary expansion vessels will be fitted elsewhere due to the height of the appliance itself. Clear access 650 deep will be required in front of the whole of the appliance for future maintenance. (2) Supplied loose - To be fitted by installer in a suitably accessible location. (3) Temperature is automatically controlled by the controller sensors S1/S2. (4) Not adjustable - Manual reset type. (5) Temperature is automatically controlled by the controller sensor therefore should not be set lower than 650C. |

|---|

TECHNICAL DATA

| Sensor Control Parameters & Default Temperature Settings | |

|---|

| Description | Sensor | Default Value (0C) |

|---|

| HP off setting (flow) | S6 | 58 |

|---|

| HP off setting (return) | S5 | 56 |

|---|

| HP on-off differential setting | S5/S6 | 3 |

|---|

| HW store heating - off setting | S3 | 60 |

|---|

| HW store heating on-off differential setting | 7 |

|---|

| HW store overheat setting | S1/S2 | 75 max. |

|---|

| Sensor S1/S2: Duplex domestic hot water overheat (store temp.) Sensor S6: Heat pump flow temperature Sensor S5: Heat pump return temperature Sensor S4: Central heating flow temperature (zone 1 circuit) Sensor S3: Domestic hot water temperature (store temperature) | HP: Heat pump CH: Central heating HW: Hot water heating |

|---|

| Notes: See Figure 1.3/1.4 for sensor locations. |

|---|

| Model Selection Data | Appliance Location |

| General guidance is given in Table 1.2. | The BoilerMate A-Class HP-DEM appliance must |

| be installed on a flat surface which is capable |

| When checking the suitability of the heat pump we recommend that the heat losses | of supporting the weight of the appliance and |

| of the external building fabric plus half of the ventilation losses are directly compared | any other ancillary equipment. (The full weight |

| to the Ecodan heat pump output of 9kW. | must be used, see table 1.2 on page 13). |

| If design calculations are carried out in the normal way, using the method set out in | The appliance sizes and the minimum cupboard |

| BS5449. The Ecodan heat pump will cope with heating systems in which boiler sizes | dimensions are shown in Table 1.2. A minimum |

| calculated in this way are rated at up to a maximum of 13kW. | of 600mm is required in front of the appliance |

| for maintenance purposes. (See figures 1.3 and |

| As the BoilerMate A-Class HP-DEM is a hot water storage appliance, we recommend | 1.4 on pages 8 and 9). |

| that the model size of the appliance is chosen by calculating the hot water volume in | |

| the normal way using the criteria set out in BS 6700 / NHBC for storage appliances. | The appliance is designed to be installed on the |

| timber plinth supplied with the appliance. |

| Electricity Supply | |

| Details of the various electrical and pipework |

| One mains supply rated at 32A, 230V~, 50Hz is required. | connections required are shown in Figures 1.3 |

| and 1.4. |

| Minimum external fuse rating and the main supply cable ratings are given in Table 1.2 | |

| Technical Data section of this manual. This appliance MUST BE EARTHED. | |

| All external wiring to the appliance must be in accordance with the latest I.E.E.Wiring | |

| Regulation, and any local regulations which may apply. | |

| The appliance shall be supplied from a suitably rated double pole isolator with a | |

| contact separation of at least 3mm in both poles. | |

| This must be suitably labelled, provide complete electrical isolation and be within 1 | |

| metre of the BoilerMate A-Class HP-DEM Unit. | |

| In the event of an electrical fault after installation of the appliance, preliminary | |

| electrical checks must be carried out i.e. Earth Continuity, Short Circuit, Polarity, and | |

| Resistance to Earth. | |

TECHNICAL DATA

Page 14

| at any time in a 24 hour cycle then a pressure |

| All recommendations with regard to pipe work systems in this manual are generally | regulating valve set at 3.5 bar should be fitted |

| based on the use of BS/EN Standard copper pipework and fittings. | downstream of the stop tap where the cold |

| supply enters the property. |

| However a plastic pipework system can be used in place of copper internally as | |

| long as the chosen system is recommended by the manufacturer for use in cold | Equipment used in the system should be |

| and hot water systems and is designed and installed fully in accordance with their | suitable for a working pressure of up to 5 bar. |

| recommendations. | |

| It is also important that if an alternative pipework material/system is chosen, the | |

| manufacturer confirms that the design criteria for the new system is at least equivalent | |

| to the use of BS/EN Standard copper pipework and fittings or larger pipe sizes are | |

| considered. | |

| In these appliances the mains inlet pressure regulating valve is set to 1.5 bar and this | |

| setting MUST NOT be adjusted.Therefore the flow rate from the appliance depends | |

| upon the resistance of the hot water supply network, capacity of the incoming | |

| mains and the characteristics of the pressure regulating valve | |

| Mains Cold Water Supply | |

| The BoilerMate A-Class HP-DEM appliance is designed to be connected directly to the | |

| mains. The combination inlet valve incorporates the required check valve. The hot | |

| water flow rate achievable is directly related to the adequacy of the cold water mains | |

| serving the property. For this reason the cold water supply to the dwelling must be | |

| capable of providing for those services which could be required simultaneously and | |

| this maximum demand should be calculated. Also if a water meter is fitted its nominal | |

| rating should match the anticipated maximum simultaneous hot and cold water | |

| demand calculated in accordance with BS 6700. This could be 60 litres per minute in | |

| some properties. 30 litres per minute is the minimum flow rate which is recommended | |

| for an adequate mains pressure system to any property. | |

| The Building Regulations L1A: New dwellings/L1B: Existing dwellings and the | |

| requirements set out in the Domestic Heating Compliance Guide specify that “where | |

| the mains water hardness exceeds 200ppm provision should be made to treat the feed | |

| water to water heaters and the hot water circuit of combination boilers to reduce the | |

| rate of accumulation of lime scale”. | |

| To comply with this requirement the hardness of the mains water should be checked by | |

| the installer and if necessary the optional factory fitted in-line scale inhibitor should be | |

| specified at the time of order for hardness levels between 200 and 300 ppm (mg/l). | |

| Where the water is very hard ie 300ppm (mg/l) and above the optional polyphosphate | |

| type, inhibitor should be specified at the time of order. However, this will need to be | |

| fitted by the installer at a suitable point in the cold water supply to the appliance. | |

| The combination valve fitted to the BoilerMate A-Class HP-DEM unit incorporates a | |

| pressure regulating valve set to provide a static operating pressure of 1.5 bar. On this | |

| basis there must be at least 2.0 bar pressure at the inlet to the appliance. This pressure | |

| must be dynamic (not static) and be available at the appliance when local demand | |

| is at its maximum. For optimum performance, and for larger properties, we would | |

| recommend that the dynamic pressure is in the range of 2.5 - 3.5 bar. | |

| The combination valve also incorporates an expansion relief valve.The discharge from | |

| this can be connected into the discharge pipe from the P & T valve. Further details of | |

| how to treat this discharge are provided later in this manual. | |

| As a general guideline, if a good pressure is available, a 15mm service may be sufficient | |

| for smaller dwellings with one bathroom. However a 22mm service (25mm MDPE) is | |

| recommended and should be the minimum for larger dwellings, or where only the | |

| minimum recommended pressure is available. | |

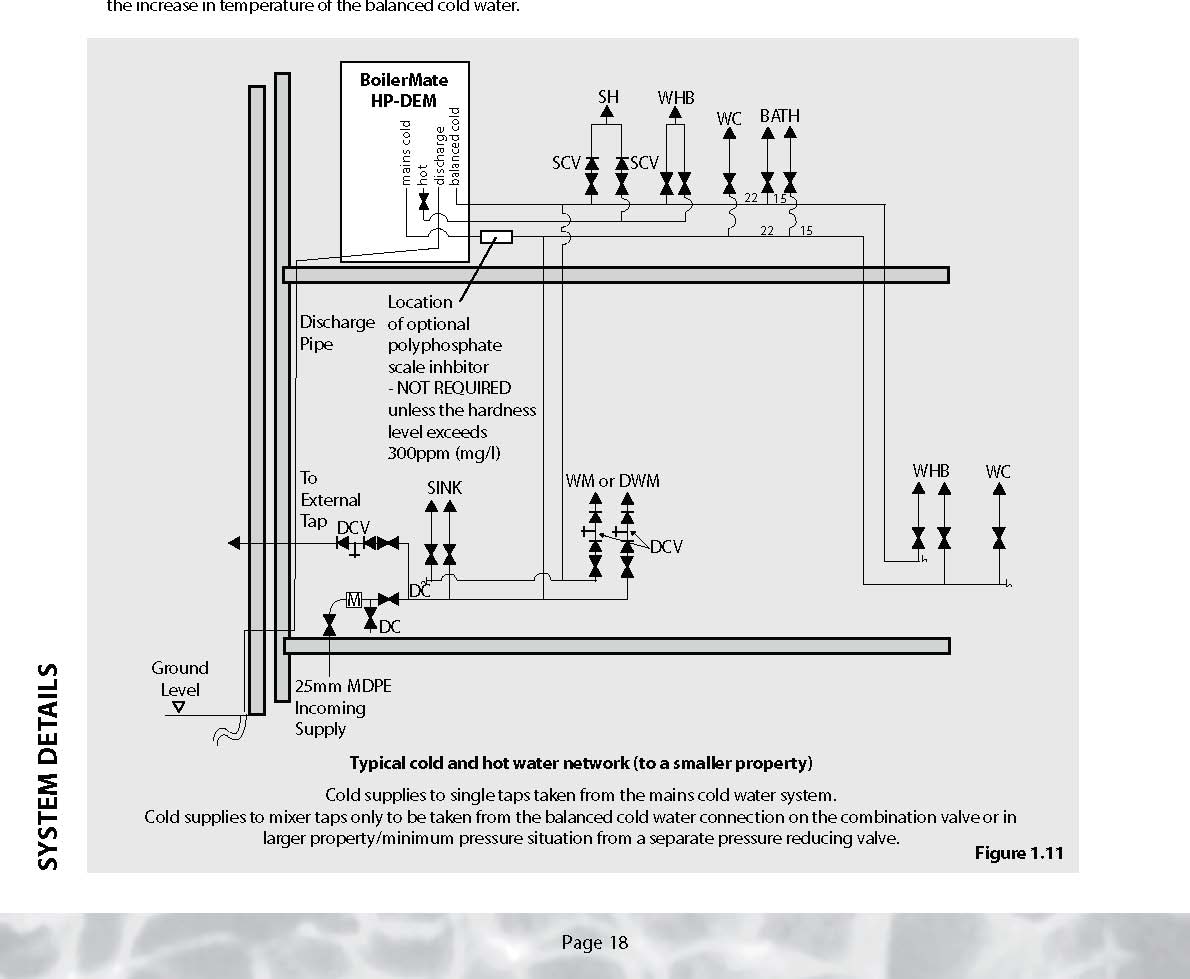

SYSTEM DETAILS

| a. | As a minimum it is recommended that the cold supply to the appliance internally is | d. If the supply to the mixer fittings (other |

|---|

| run in 22mm copper (or equivalent in plastic) and then from the appliance, hot and | than a dual outlet type) is not taken |

|---|

| cold services are in 22mm past the draw-off to the bath. For large properties bigger | from the balanced supply the system will |

|---|

| sizes will be necessary and these should be proved by calculation in accordance | become over pressurized and cause the |

|---|

| with BS6700. It is recommended that flow regulators are provided in the branch | pressure relief valve to discharge. Over |

|---|

| to each terminal fitting (or in the fitting itself ) to ensure best use is made of the | time this could also cause the premature |

|---|

| available pressure/flow. | failure of the appliance itself which will |

|---|

| not be covered by the warranty. |

|---|

| b. The highest hot or cold water draw-off point should not exceed 4 metres above | |

|---|

| the combination inlet valve fitted to the appliance. | e. | Whenever possible the hot and cold water |

|---|

| supply to a shower-mixing valve should be |

|---|

| c. | In average size dwellings, the cold water supply to any mixer fittings (other than | the first draw-off point on each circuit. |

|---|

| dual outlet fittings) should be taken from the balanced cold outlet connection on | |

|---|

| the combination valve fitted to the appliance. However, in larger dwellings with | f. | It is important that the mains cold water |

|---|

| a number of bathrooms and en-suites and/or long pipe runs, the balanced cold | | pipe work is adequately separated from any |

|---|

| supply must be provided with its own pressure regulating valve (set at the same | | heating/hot water pipe work to ensure that |

|---|

| pressure as the one provided with the appliance ie 1.5 bar static) and not taken from | | the water remains cold and of drinking water |

|---|

| the appliance. When a separate pressure regulating valve is used for the balanced | | quality. |

|---|

| cold water supply, it is recommended that a small expansion vessel (0.25 - 0.5 litre) | |

|---|

| is fitted after the pressure regulator to accommodate the pressure rise caused by | |

|---|

| | Water Circulation |

| a. | Ensure that all terminal fittings are suitable for mains pressure in the range of 0.5 | |

| - 1.5 bar. Use aerated taps whenever possible to prevent splashing. | If the dead leg volume of the hot water draw-off |

| | pipework is excessive and the delivery time for |

| b. Any type of shower mixing valve can be used as long as both the hot and cold | hot water to be available at the tap is more than |

| supplies are mains fed. However, all mains pressure systems are subject to dynamic | 60 seconds you may consider using:- |

| changes particularly when other hot and cold taps/showers are opened and closed, | |

| which will cause changes in the water temperature at mixed water outlets such | a. Trace heating such as the ‘Raychem HWAT’ |

| as showers. For this reason and because these are now no more expensive than | s ystem. Pl eas e c al l Gledhil l tech nical |

| a manual shower we strongly recommend the use of thermostatic showers with | department for further details. |

| this appliance. | |

| The shower head provided must also be suitable for mains pressure supplies. | OR |

| If it is proposed to use a ‘whole body’ or similar shower with a number | |

| of high flow/pressure outlets please discuss with the Gledhill technical | b. A secondary hot water circulation system as |

| department. | shown schematically in figure 1.9. |

| c. | Note that the shower fittings must comply with the backflow prevention | |

| requirements (Para 15, Schedule 2) of the Water Supply Regulations. | |

| d. A bidet can be supplied from the BoilerMate A-Class HP-DEM appliance as long as | |

| it is of the over rim flushing type and incorporates a suitable air gap. | |

SYSTEM DETAILS

General

Warning: BoilerMate A-Class HP-DEM is an unvented hot water storage appliance and therefore it is not suitable for use with a solid fuel boiler, steam or any other uncontrolled heat source.

The BoilerMate A-Class HP-DEM is designed to be sold as part of a package with the Mitsubishi Electric Ecodan air source heat pump. The combination of the BoilerMate A-Class HP-DEM and the Mitsubishi Electric Ecodan air source heat pump has been the subject of independent testing by BRE and a report is available on request.

The heating system design and installation must comply with the requirements of BS 6798 and BS 5449 for the performance parameters chosen for the system.

Plastic Pipework

All recommendations with regard to pipework systems in this manual are generally based on the use of BS/EN Standard copper pipework and fittings. However plastic pipework can be used in place of copper internally as long as it is recommended by the manufacturer and installed fully in accordance with their recommendations.Barrier type plastic pipework should always be used for these systems.

It is important to ensure that if the system is to be installed using plastic pipework it is designed and sized using the parameters for plastic pipework.

Selection/Heat Pump Sizing

General model selection guidance is given in Table 1.2 Technical Data.

Heat Pump Primary Circuit

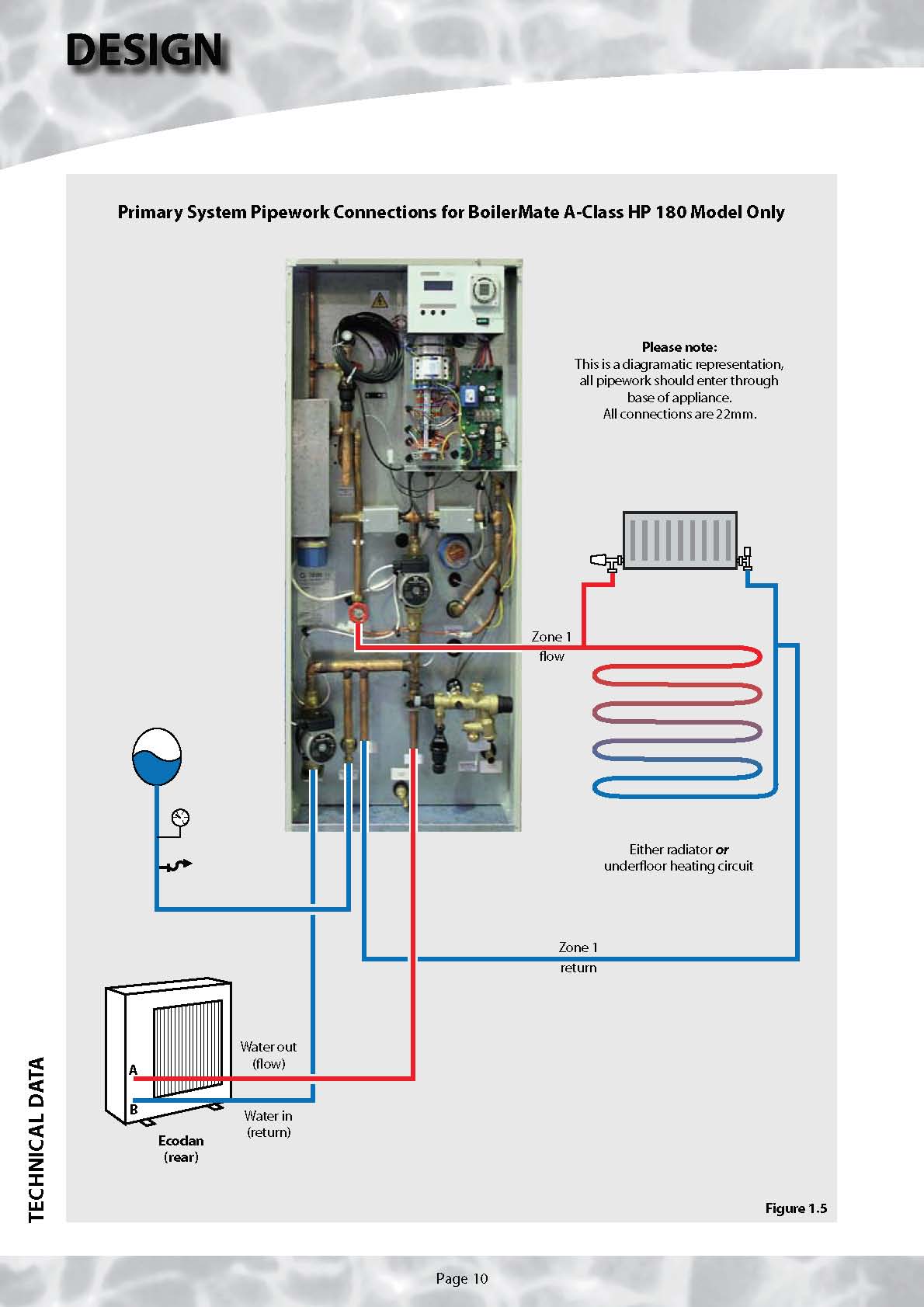

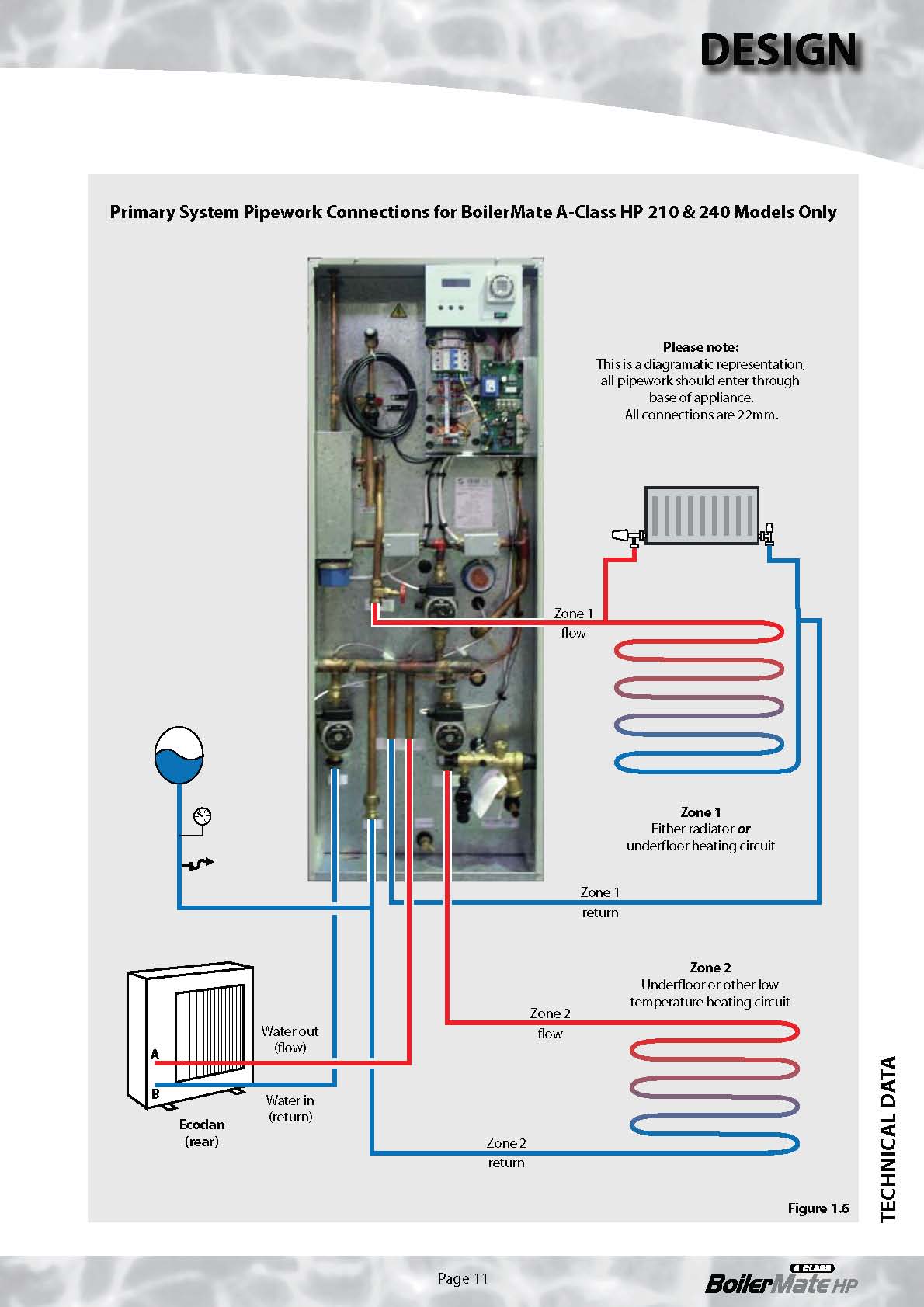

The flow and return from the heat pump must run directly to the connections provided on the BoilerMate A-Class HP-DEM appliance.

A Fernox Boiler Buddy is provided as part of the package and this must be fitted internally on the return circuit as close as practical to the heat pump unit fully in accordance with the manufacturers instructions included later in this manual.

Central Heating Circuits

These should be sized in the normal way to suit the flow and return temperatures for the system chosen. The flow and return pipework should be connected directly to the connections provided.

If the heat pump/BoilerMate A-Class HP-DEM appliance is being fitted to an existing heating system, this must be thoroughly flushed/cleaned before the appliances are fitted.

Summer Towel Rail Circuit

If a separate summer towel rail circuit is required, this and the zone 1 CH circuit will need to be arranged as separate zones complete with their own time and temperature controls. Channel 2 on the clock provided on the appliance will then need setting to constant (continuous) operation mode. The wiring should be taken from the zone 1 room thermostat terminals. For further details, please contact the Gledhill Technical Helpline on 08449 310000.

The BoilerMate A-Class HP-DEM appliance should not be installed in a location where the contents could freeze. Suitable precautions should be taken to protect the heat pump/ pipework as recommended in the heat pump section of this manual.

User Controls

A 2 channel digital programmer is fitted to the front of the appliance.A separate external room thermostat will normally be required for the central heating.

Heating System Bypass

Automatic bypass valves will be required in the heating systems if it is proposed to fit thermostatic radiator valves (TRV’s) to all radiators or fit zone valves to control all the separate heating circuits. To meet the requirements of Building Regulations for a boiler interlock, it is recommended that the radiator in the area where the room thermostat is installed should be fitted with lock shield valves on both connections.

Appliance Primary Pipework/Coil Volumes

Note: With the 210/240 models, the sealed primary system filling/expansion kit will need to be connected to the Zone 2 return connection or branched into the return pipework.

When calculating the total system volume,allow 10 litres for the primary pipework/coils within the appliance.

Sealed System kit For The Central Heating System

An optional sealed system kit as follows can be supplied with the BoilerMate A-Class HP-DEM.

- Pressure gauge (0 – 4 bar)

- Primary expansion vessel charged to 1.0 bar, (Size depends upon the model, see Table 1.1)

- WRAS approved primary system filling loop

External Temperature Compensation Sensor

This is supplied connected to 10 metres of cable which is coiled and cable tied to the pipework at high level in the appliance and will need to be mounted on an external wall and wired back to the BoilerMate A-Class HP-DEM appliance using the cable supplied. The sensor shall be located in a position which is not unduly affected by wind/direct sunlight etc. On this basis a sheltered location on a north facing wall is recommended.

SYSTEM DETAILS

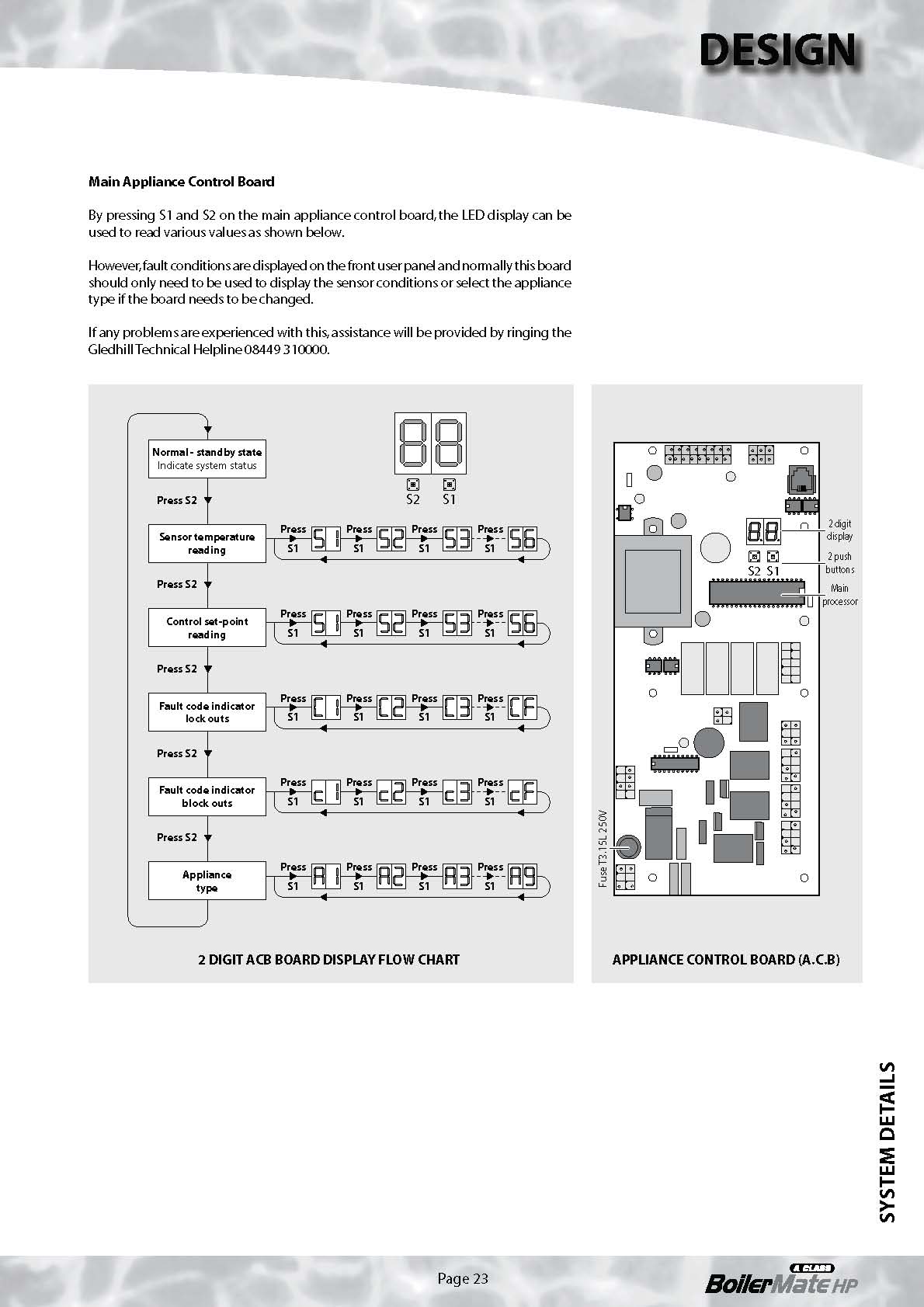

Front Panel User Controls

The front panel user controls are shown in the picture opposite and their functions

are described below.

Different windows can be accessed in the visual display panel on the front of the

appliance to indicate various temperatures and fault conditions.

2 Channel Clock

A 2 channel Grasslin clock is provided to allow separate control of the hot water and

heating requirements in accordance with the latest Building Regulations. Details of

how to set the clock are provided on the User label and in the User Instructions.

Channel 1 controls the operating times for the domestic hot water heating circuit.

This should normally be set to constant to allow the hot water to be available 24

hours a day.

Channel 2 controls the operating times for the zone 1 central heating circuit and

should be set to suit the householders lifestyle.

Note: Electrical connections are provided on the terminal strip for a room thermostat.

With the two larger models, separate time and temperature controls such as a remote

programmable room thermostat will be required for the zone 2 central heating circuit.

Electrical connections are also provided for this on the terminal strip.

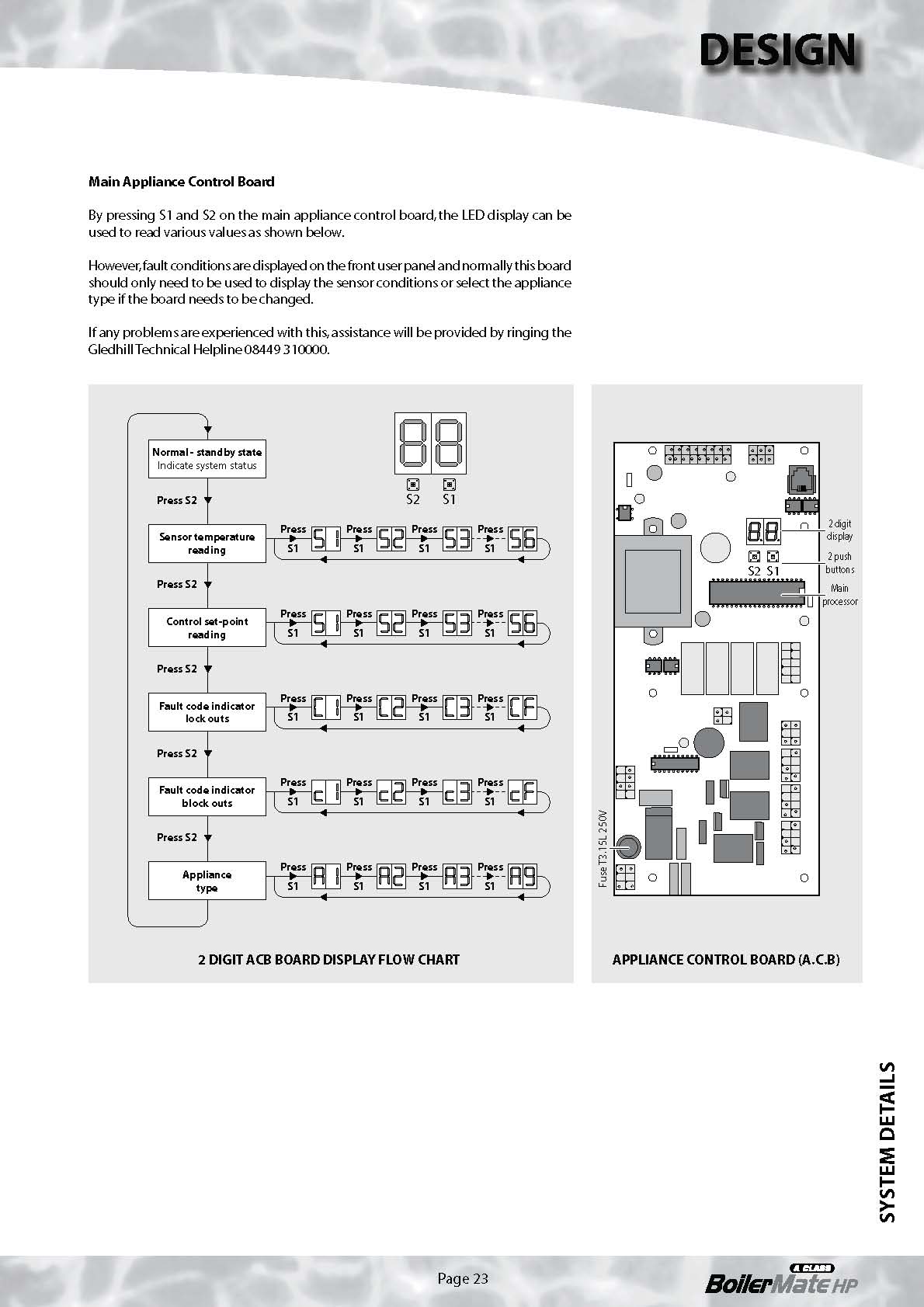

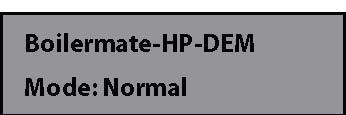

Normal operating display

Normal Operating Display Window

In normal automatic heat pump operation the display will be as shown opposite.

Switch Operating Display Window

If a fault occurs with the heat pump, the ‘Switch’ emergency electric back-up system Switch operating display can be selected by pressing and holding the ’Switch’ button below the display for at

least 5 seconds. The ‘Normal’ will change to ‘Switch’ and will flash.

Once the problem has been resolved, the appliance can be returned to normal operation by pressing the ‘Switch’ button for at least 5 seconds.

Fault Condition Display Window

Fault condition display

If a fault occurs with the BoilerMate A-Class HP-DEM appliance the window will automatically display the fault condition. The window will flash alternately between the two displays shown opposite.

The first window shows the fault reference code.

The second window shows a description of the actual fault condition. Fault condition display

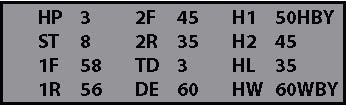

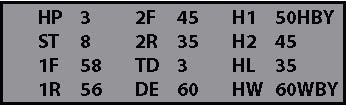

Control/Status Display Window

By pressing the select button once when the window is in the normal operating mode, the current temperatures and the status of the sensors/pumps can be seen as shown typically opposite - also see Table 1.3 on page 12.

Control/sensor status display - current

By pressing the select button twice, the set point values that are being used can be

SYSTEM DETAILS

seen as shown opposite.

Control Circuit Power Switch

This switch only controls the supply to the appliance control circuit. For service the appliance must be isolated at the appropriate 2-pole isolator fitted adjacent to the appliance. Control/status display - set points

Page 22

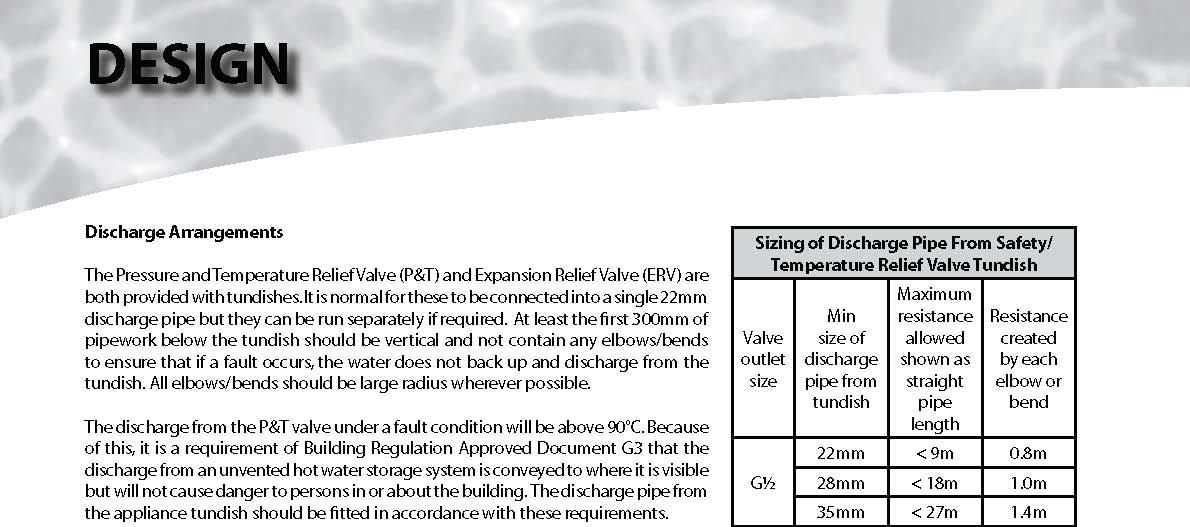

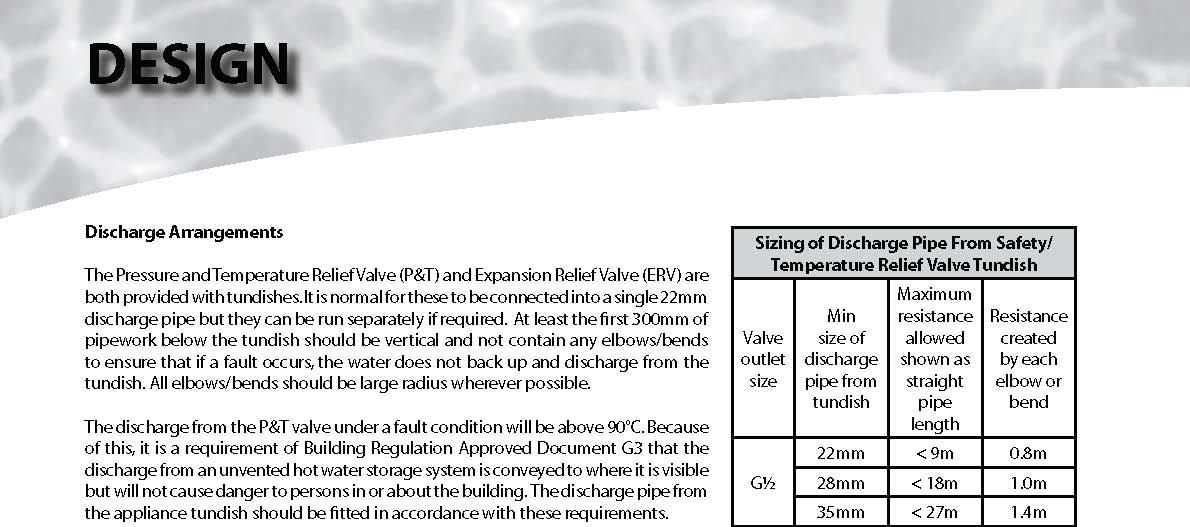

The Pressure and Temperature Relief Valve (P&T) and Expansion Relief Valve (ERV) are both provided with tundishes.It is normal for these to be connected into a single 22mm discharge pipe but they can be run separately if required. At least the first 300mm of pipework below the tundish should be vertical and not contain any elbows/bends to ensure that if a fault occurs, the water does not back up and discharge from the tundish. All elbows/bends should be large radius wherever possible.

The discharge from the P&T valve under a fault condition will be above 90°C. Because of this, it is a requirement of Building Regulation Approved Document G3 that the discharge from an unvented hot water storage system is conveyed to where it is visible but will not cause danger to persons in or about the building. The discharge pipe from the appliance tundish should be fitted in accordance with these requirements.

The discharge pipe MUST terminate in a SAFE and VISIBLE position. For a 22mm discharge it must have an equivalent length of no more than 9 metres and it must have a continuous fall (1:200 minimum) throughout its length. Above 9 metres equivalent length, the pipe diameter must increase to meet the requirements of the table shown opposite.

An example of how to calculate the size required is as follows: A G½ temperature relief valve has a discharge pipe with 4 elbows and length of 7m from the tundish to the point of discharge. From the table opposite, maximum resistance allowed for a straight length of 22mm copper discharge pipe from a G½ temperature relief valve is 9.0m. Subtract the resistance for 4 No. 22mm elbows at 0.8m each = 3.2m. Therefore the maximum permitted length equates to 5.8m. 5.8m is less than the actual length of 7m therefore calculate the next largest size. Maximum resistance allowed for a straight length of 28mm pipe from a G½ temperature relief valve equates to 18m. Subtract the resistance for 4 No. 28 elbows at 1.0m each = 4m. Therefore the maximum permitted length equates to 14m. As the actual length is 7m, a 28mm copper pipe will be satisfactory.

In apartment/flat situations the discharge pipes can be connected into a single pipe which is discharged at low level. In this case the number should be limited to 6 to allow the fault to be easily traced. The single pipe should be at least one size larger than the largest individual discharge pipe connected to it.

The discharge can consist of scalding water and steam therefore the pipework should be metal. The following locations for the discharge pipe are acceptable:

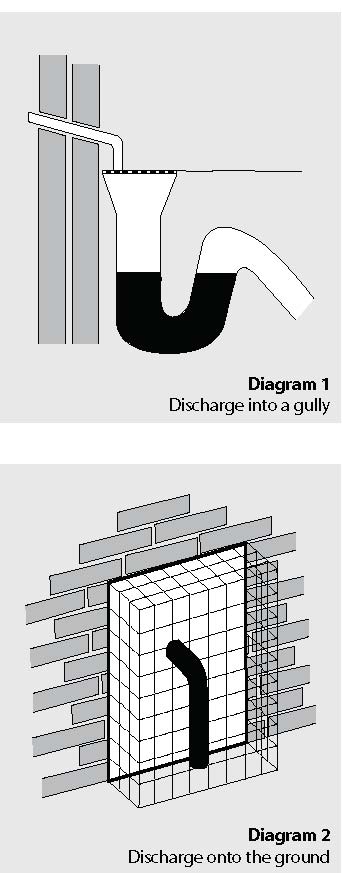

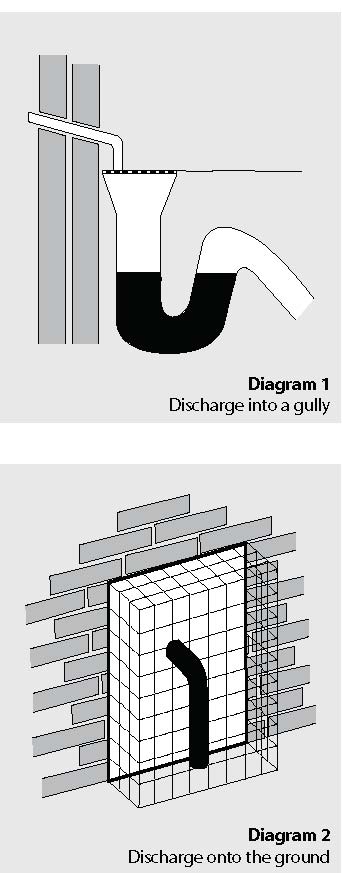

Low Level

- Into a gully below the grating but above the water level (see diagram 1).

- Onto the ground(drive,path or garden area).The pipe should discharge downwards and be no more than 100mm above ground level. A wire cage should be provided to prevent people coming into contact with scalding water (see diagram 2).

High Level

High level discharge is only acceptable if it is :

• onto a flat or pitched roof capable of withstanding high temperature water and at least 3m away from plastic guttering. or

• into a metal hopper and down pipe which terminates at low level (as described above.)

Discharge into a soil or waste pipe (whether plastic or metal) is not acceptable.

The proposals for the discharge pipe/termination point should be discussed and agreed with the Building Control Officer prior to commencing any work.

Further details are given in approved Document G3 of the Building Regulations.

SYSTEM DETAILS

relevant minimum dimensions are provided in Table 1.2 Technical Data.

Because of the ease of installation we recommend that the cupboard construction is completed and painted before installation of the appliance. The cupboard door can be fitted after installation.

If the unit needs to be stored prior to installation it should be stored upright in a dry environment and on a level base/floor.

Installation and maintenance access is needed to the front and top of the appliance. See Table 1.2 Technical Data for further details.

The minimum dimensions contained in Table 1.2 Technical Data allow for the passage/ connection of pipes to the appliance from any direction as long as the appliance is installed on the installation base provided. If the installation base is not used extra space may be needed to allow connection to the pipework and the whole of the base area should be continuously supported on a material which will not easily deteriorate if exposed to moisture.

The floor of the cupboard needs to be level and even and capable of supporting the weight of the appliance when full. Details of the weight when full is provided in Table

1.2 Technical Data.

The appliance is designed to operate as quietly as practicable. However, some noise (from pumps etc) is inevitable in any heating system. This will be most noticeable in cupboards formed on bulkheads, or at the mid span of a suspended floor. In these cases the situation can be improved by placing the appliance on a suitable sound deadening material (i.e. carpet underlay or similar).

The appliance is very well insulated and no ventilation is normally required to the cupboard.

A suitable location will be needed for the unvented store expansion vessels. This will often be on top of the appliance itself or at high level in the cupboard housing the BoilerMate A-Class HP-DEM appliance. The dimensions and clearances are shown in section 1.2 Technical Data. A location is also required for the primary system expansion vessel as well as a suitable route for the connecting pipe from the BoilerMate A-Class HP-DEM appliance to the expansion vessel. A suitable route and discharge location will also be required for the discharge pipe from the P & T valve and ERV for all models.

An electrical supply must be available which is correctly earthed, polarized and in accordance with the latest edition of the IEE requirements for electrical Installations BS 7671.

The electrical mains supply needs to be 230V AC/50Hz/Single Phase.

Connection must be made using a double-pole linked isolator with a contact separation of 3mm in both poles which is located within 1m of the appliance. The supply must only serve the appliance.

The supply to all models shall be rated at 32 amp.

SITE REQUIREMENTS

Preparation/placing The Appliance In Position

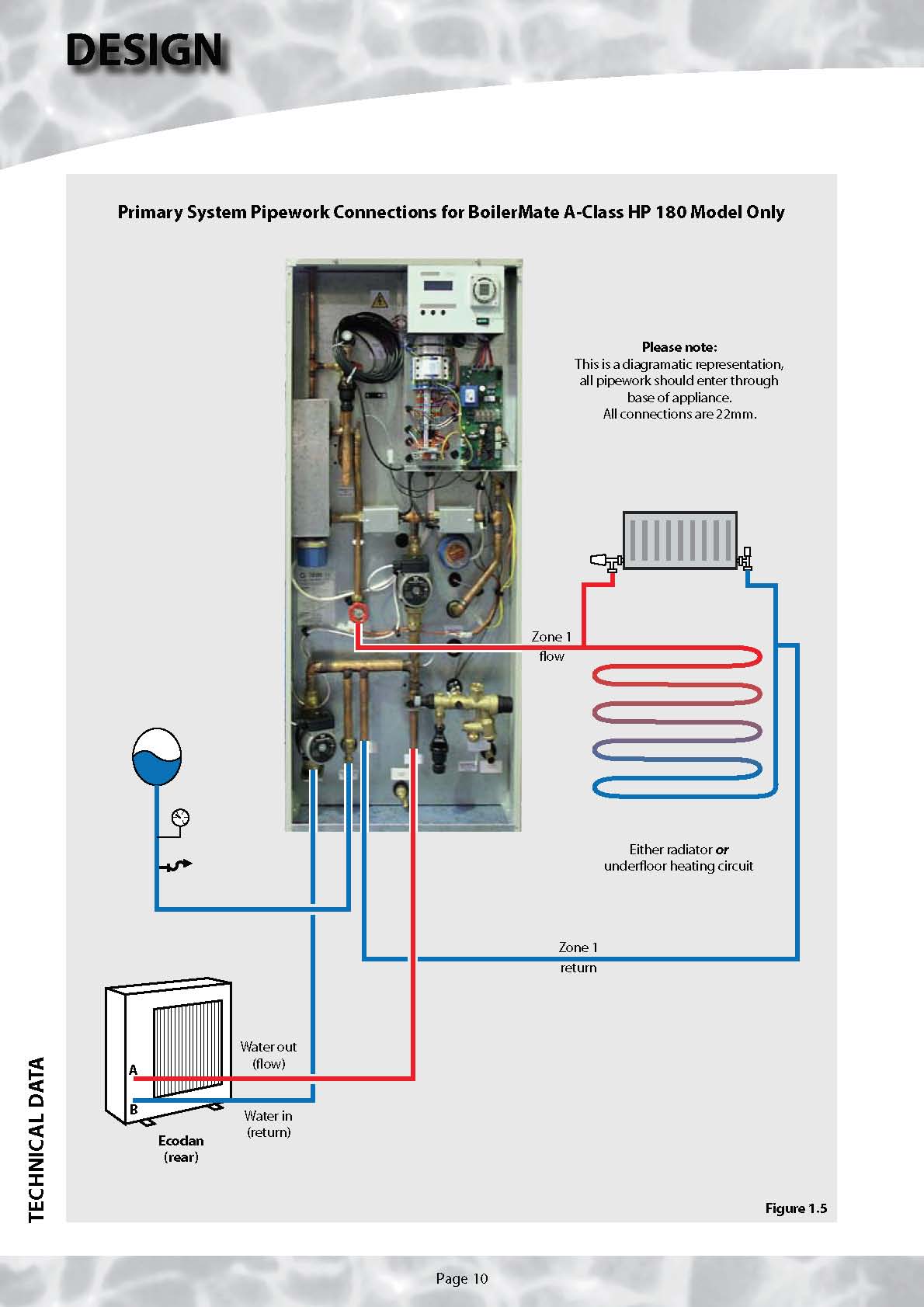

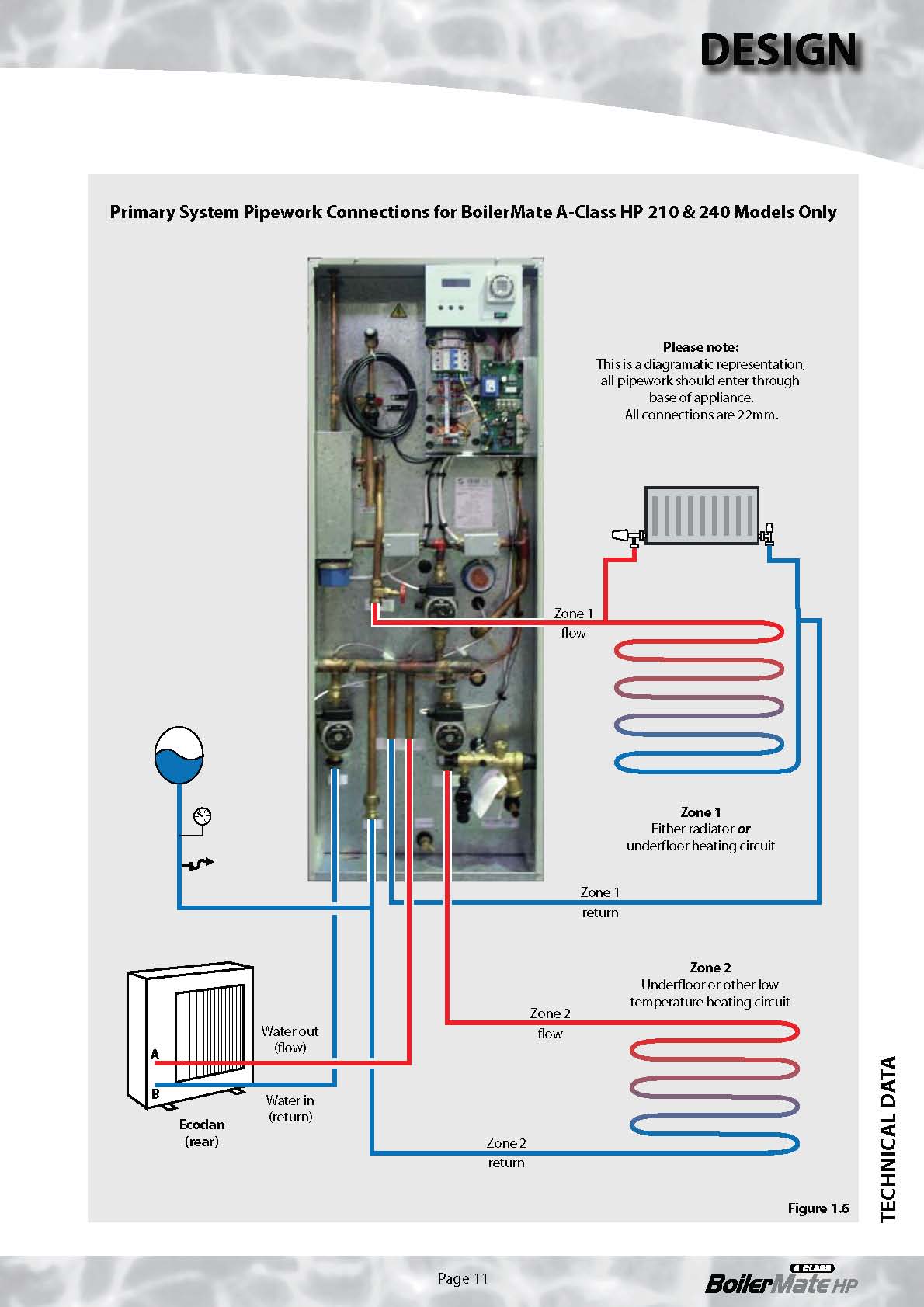

Details of the recommended positions for termination of the first fix pipework are provided in figures 1.5 and 1.6. The pipework can be located or its position checked using the template provided with each appliance. If these have been followed, installation is very simple and much quicker than any other system. The appliance is supplied shrink wrapped on a timber installation base. Carrying handles are also provided in the back of the casing.

If the optional primary sealed system kit is ordered this will be supplied in a separate box.

It is the installers responsibility to check that the size of expansion vessel provided is adequate for the primary/heating system being installed.

The appliance should be handled carefully to avoid damage and the recommended method is shown opposite. Further details are provided on page 4 and Appendix D of these instructions. Before installation the site requirements should be checked and confirmed as acceptable. The plastic cover and protective wrapping should be removed from the appliance and the installation base (provided) placed in position.

The appliance can be then be lifted into position in the cupboard on top of the base and the front panel removed by unscrewing the 2 screws and lifting the door up and out ready for connection of the pipework and electrical supplies. If they are not being fitted on top of the appliance a suitable support shall be installed for the unvented store expansion vessels.

The primary sealed system filling/expansion kit should be fitted on the supports provided and piped to the connection point provided on the BoilerMate A-Class HP-DEM appliance complete with a manual air vent at the high point.

INSTALLATION

Page 26

INSTALLATION

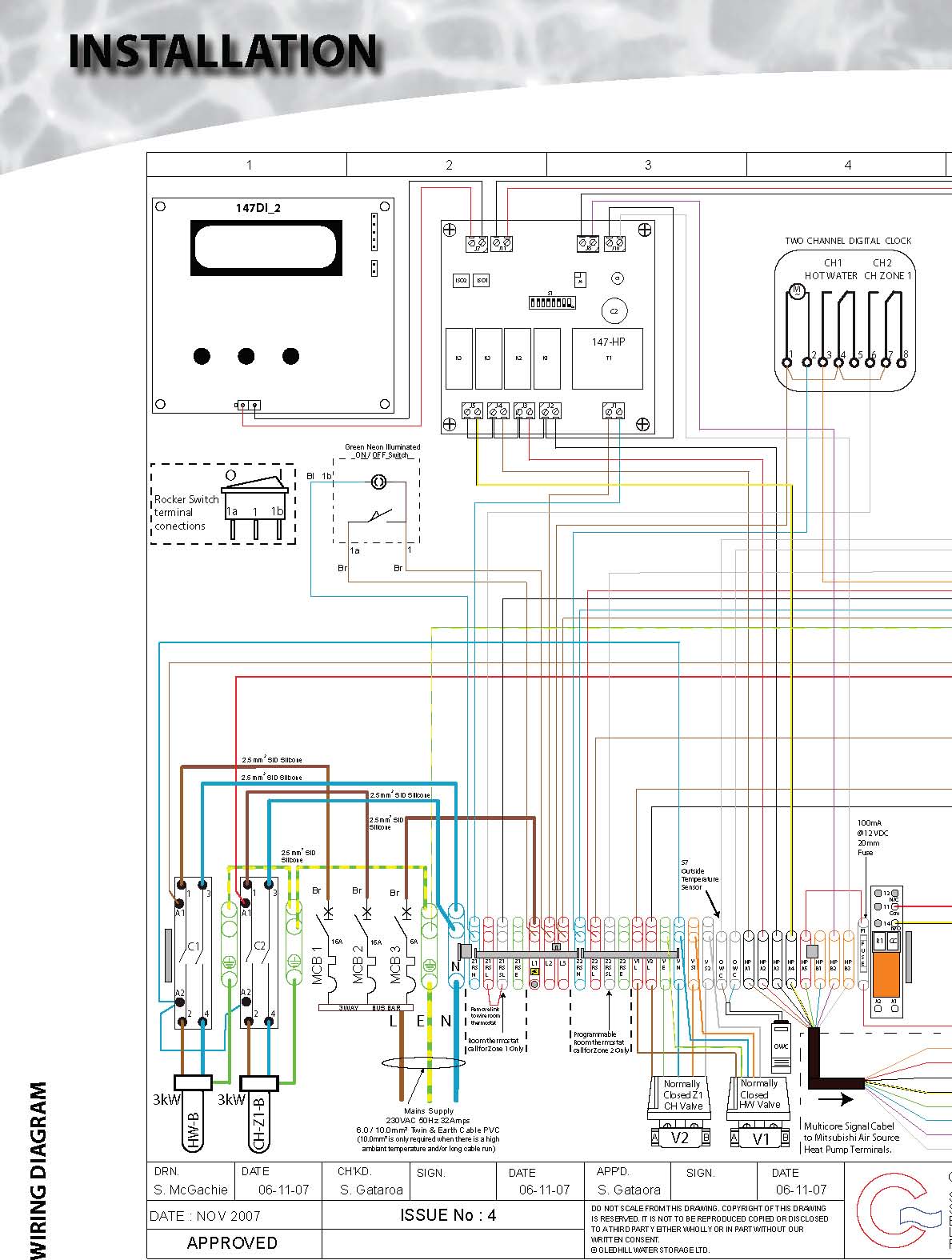

Electrical Connection - Appliance

All the power and control functions of the

6A

16A

16A

BoilerMate A-Class HP-DEM are pre-wired to a

Z2

Z2

Z1

Z1

Z1

Z1

Z2

Z2

V1

Z2

V2

V

V

L1

L2

L3

RS

RS

RS

RS

RS

RS

RS

L

L

N

RS

E

N

E

N

L

SL

E

N

SL

L

Document P) and the IEE Requirements for

L

BUS BAR

Electrical Installations BS 7671. Details of the

Remove link to wire room thermostat

terminal strip located at high level inside the appliance. The wiring to the appliance shall be carried out by a competent person in accordance with the Building Regulations (Approved

necessary wiring are shown opposite and on the electrical schematic drawing (see pages 26 and 27).

All the terminals are suitably labelled on the appliance.

Note: Do not attempt the electrical work unless

Use to connect the

CH zone 2 time and

temperature controls

to the BoilerMate

A-Class HP-DEM

appliance

is in accordance with the Site Requirements and ensure that it is isolated.

Blk Br Bl G/Y The heat pump wiring instructions (Appendix A) should be read in conjunction with this

3 12

10 / 6 mm Supply Cable

you are competent to carry it out to the above

230V 50Hz AC

32 amp supply from a double pole isolator located within 1 metre

of the appliance

standards.

Before commencing check that the power source

manual.

Run the external wiring through the service slot provided in the base of the appliance. Make the connections as shown opposite on

Room thermostat (Zone 1) the terminal strip provided.

The room thermostat should be wired as shown opposite. The link in Z1RSL to Z1RSSL must be

removed when the room thermostat is fitted.

The time and temperature controls for CH zone 2 should be wired as necessary into the Z2 terminals provided.

Before switching on the electrical supply c h e c k a l l t h e f a c to r y m a d e t e r m i n a l connections to ensure they have not become loose during transit.

Frost/Building Fabric Protection

When frost protection is required for the whole house set channel 2 of the clock to constant during the time required and adjust the room thermostat to a suitable setting.

INSTALLATION

Page 28

| System |

| Check and adjust as necessary the hot water system expansion vessel(s) air pressure | |

| to 1.5 bar. | If it is proposed to ‘powerflush’ the heating |

| system always check and comply fully with |

| Check that any drain valves are closed then open the incoming stop valve and fill the | t he m a n u f a c turer s in s t r u c t i o n s fo r t he |

| domestic mains cold and hot water systems in the normal way ensuring there is no | powerflushing equipment being used. |

| air trapped in the system. | |

| It is recommended that the heat pump and the |

| Check and adjust as necessary the primary heating system expansion vessel to the | BoilerMate A-Class HP appliance is bypassed |

| figure specified (normally 1.0 bar). | during powerflushing of the primary/heating |

| system. |

| Note: The expansion vessel pressures should be checked before the systems are | |

| filled. | If in any doubt please consult our Technical |

| Helpline. |

| Fill the primary heating system with potable water through the filling loop provided | |

| to the pressure required (normally 1.0 bar). | Cleansing the Hot/Cold Water System |

| During filling vent air as necessary from the high points of the system including | Fully flush and, when necessary, chlorinate the |

| the manual air vents provided on the appliance and on the feed to the expansion | hot and cold water system in accordance with |

| vessel. | the recommendations in the Model Water |

| Byelaws and BS 6700. |

| Check the whole of the primary heating and domestic hot and cold distribution | |

| systems for leaks. | Remove and clean the strainer element in the |

| combination inlet valve, then replace it and re- |

| It is essential that all systems functions properly for optimum performance. | fill the systems. |

| To achieve this,the primary system should be commissioned in accordance with good practice | Once the systems have been refilled manually |

| and generally in accordance with the requirements of BS 6798, BS 5449 and BS 7593. | open the relief valves one by one and check |

| that water is discharged and runs freely through |

| When using either cleansing or corrosion inhibitor chemical, the manufacturers | the tundish and out at the discharge point. The |

| instructions must be followed. | pipework should accept full bore discharge |

| without overflowing at the tundish, and the |

| Cleansing the Primary System | valve should seat satisfactorily. |

| It is very important to ensure that the Primary system is cleaned using a suitable | On completion, check the pressure in the |

| cleansing agent such as Fernox F3 to ensure that any flux residues/installation | primary system is correct and disconnect the |

| debris are removed. | manual filling loop. |

| The cleaning should be carried out fully in accordance with the manufacturers | |

| instructions. To allow thorough flushing, full bore drain valves should be provided. | |

| Primary Water System Treatment | |

| Although the BoilerMate A-Class HP-DEM has no special water treatment requirements, | |

| the radiators and other parts of the circuit will require the application of a scale and | |

| corrosion inhibitor.The heat pump and external connecting pipework will also require | |

| protection against freezing. For this reason a combined anti freeze and inhibitor | |

| product such as Fernox Alphi 11 must be used. | |

| The volumes/concentration should be calculated in accordance with the manufacturers | |

| instructions allowing 10 litres for the volume for the primary pipework/coil in the | |

| BoilerMate A-Class HP appliance. | |

| We consider that in typical radiator systems, the total water volume will not exceed | |

| 80 litres. On this basis, 20 litres of Alphi-11 will provide at least the 25% concentration | |

| recommended by the manufacturer as the minimum.However,because of the volumes | |

| experienced in underfloor system, the system volume for these types of systems will | |

| need to be calculated. | |

| The Fernox Boiler Buddy supplied separately with the appliance package should be | |

| installed internally on the heat pump return as near as practical to the heat pump | |

| - see page 48 for further details. | |

COMMISSIONING

COMMISSIONING

The built in controls should ensure compatibility if the heat pump and the BoilerMate A-Class HP-DEM appliance. They will automatically control the two appliances once both appliances are energised.

Turn on the BoilerMate A-Class HP-DEM and check that the sensors and all controls operate correctly as well as any motorised valves. Check that no water discharges from either the expansion valve or temperature and pressure-relief valve during the heating cycle.

Do not switch on MCB1 and MCB2 to activate the CH and DHWS electric boost systems until the primary systems have been commissioned.

Check the appliance, the heating system and hot water system for leaks when hot.

System Commissioning

Check that the correct outlet pressure is being maintained on the domestic water systems by the pressure reducing valve by checking the pressure at a hot tap or in the tapping provided on the combination inlet valve.

Check the correct flow is being achieved at each tap and the implications of opening more than one tap at the same time. If necessary fit flow regulators to each tap if these have not already been provided.

The heating systems and pumps should be set and balanced in the normal way to provide the temperature differential in line with the system design parameters chosen.

The primary system and pump to the heat pump should normally be set to speed 3.

If an automatic bypass valve is provided on the primary/heating circuit, check/adjust this as necessary to suit the particular installation requirements.

The room thermostat/clock or programmable room thermostat controls the heating and hot water systems and should be set to suit the householders requirements using the instructions provided with the controls.

This product is covered by the ‘Benchmark’ scheme and a separate commissioning/service log book is included with this product. This must be completed during commissioning and left with the product to meet the Warranty conditions offered by Gledhill.

On completion:-

- Do ensure that the electrical connections (e.g. mains supply, room thermostat) to the unit are correct and tight.

- Do ensure that all the pipework connections in the appliance are tight and not leaking.

- Do ensure that any pipework particularly plastic adjacent to the appliance is adequately supported and anchored.

- Do ensure that the functioning and control of the system is explained to the occupant and explain the need and importance of periodic servicing.

These Instructions should be replaced along with the component manufacturers instructions in the pocket provided on the appliance and the front panel refitted.

NOTE:-With sealed heating systems air is released from the water during the first few weeks of operation. This must be vented and the system repressurised.

If the system is not likely to be used continuously after testing/commissioning it should be isolated from the water and electricity supply and either drained down or have the pressure removed from both the heating and water systems.

Important Do’s and Don’ts

DO check the incoming mains water pressure and flow rate are adequate. (The preferred range of mains pressure is 2.5-3.5 bar).

DO check and ensure that the air pressure side of the hot water expansion vessel(s) is set at

1.5 bar.

DO check that all plumbing and electrical connections are in accordance with the labelling on the unvented storage appliance.

DO insulate any exposed pipework in the BoilerMate A-Class HP-DEM cupboard and insulate/waterproof the external pipework to the heat pump.

DO check the pump settings give the correct temperature difference across the flow and return in the primary/heating circuits.

DO ensure that the bypass valve is set correctly.

DON’T operate any immersion heaters until the appliance/systems are fully filled, vented and commissioned.

DON’T place any clothing or other combustible materials against or on top of this appliance.

DO ensure that the discharge pipework from the relief valves is/are installed to a fall and are of the correct size so that water does not overflow when a relief valve operates.

DO ensure the discharge point is safe and in accordance with the G3 Building Regulations.

DO check and ensure the air pressure side of the heating expansion vessel is set at 1.0 bar (or as specified).

DO check that the primary system pressure does not exceed 2 bar when the whole of the primary/heating system are up to temperature.

DO ensure that all systems are thoroughly flushed and cleaned and that a Fernox Boiler Buddy is fitted internally on the return as near as possible to the heat pump.

DO ensure that the inhibitor used is a combined product incorporating antifreeze and that sufficient has been added to provide at least the minimum concentration level recommended by the manufacturer.

Page 32

Servicing/Maintenance

The Registered Installer is responsible for the safe installation and operation of the system. He must also make his customer aware that periodic checks of the equipment are required by the Building Regulations and essential for safety.

Maintenance and inspection periods will vary for many reasons. Gledhill Water Storage Ltd recommend a maximum of 12 months between inspections. Experience of local water conditions may indicate that more frequent inspection is desirable, eg. when water is particularly hard and scale-forming or where the water supply contains a high proportion of solids, eg. sand. For Maintenance see the table below:

| 1 | With the water supply turned off, remove the screen from the strainer in the combination inlet valve and clean off any detritus (dirt). |

| 2 | With the water supply turned off and the hot taps open, check the expansion vessel charge pressure and top up as necessary (1.5bar). |

| 3 | With the water supply turned on, open the temperature relief valve and then expansion valve to check for unrestricted discharge into tundish. Check valves for freedom of movement and confirm that the water stops and both valves reseat correctly. Check at a full bore discharge from either valve that there is no back up or discharges over the tundish. |

| Check that the correct outlet pressure is being maintained by the pressure |

| 4 | reducing valve by recording the presure at a terminal fitting or the tapping |

| provided on the combination inlet valve. |

| 5 | Clean flow regulators (or restrictor/aerators) on each terminal fitting tap/ shower as applicable. Check for correct flow rate at terminal fittings. |

| 6 | Visually inspect, checking for the presence of supplementary bonding and that it is being maintained. |

| 7 | Check correct rating and type of fuse is fitted on the electrical supply. |

| 8 | Check for the correct operation and temperature setting of the thermostats. |

| 9 | Check the operation of the motorised valves. |

| 10 | Check the operation of ‘Switch’. |

| 11 | If necessary descale the heat exchangers immersion/heaters in hard water |

| areas. |

The Registered Installer is responsible for the safe installation and operation of the system. He must also make his customer aware that periodic checks of the equipment are required by the Building Regulations and essential for safety.

Maintenance and inspection periods will vary for many reasons. Gledhill Water Storage Ltd recommend a maximum of 12 months between inspections. Experience of local water conditions may indicate that more frequent inspection is desirable, eg. when water is particularly hard and scale-forming or where the water supply contains a high proportion of solids, eg. sand. For Maintenance see the table above:

The above service/maintenance recommendations relate to the BoilerMate A-Class HP-DEM appliance only. Any service of the heat pump/heating system should include checks on the water pressure in the primary/heating systems and the air pressure in the primary expansion vessel with the system pressure removed.

Service of the heat pump is covered elsewhere in this manual. It is recommended that the Fernox Boiler Buddy is checked and cleaned at the same time as the BoilerMate A-Class HP-DEM appliance is serviced. The concentration of the inhibitor should also be checked and if necessary topped up with Alphi-11 to at least the minimum 25% level recommended by the manufacturer.

Changing Components

If it is necessary at any time to drain the storage vessel either for system modifications or to replace a component the appliance must be drained in the following way.

Before draining open all hot taps in the system then hold open the pressure and temperature relief valve until water stops discharging into the tundish.

Open the drain cock and immediately hold open the P & T relief valve again. This must be held open until the cylinder is completely drained.

When the unit is re-filled ensure the drain valve does not leak.

The KIWA Approvals for the BoilerMate A-Class HP-DEM appliance are conditional on the specific manufacturer/type of components fitted and any replacements must be purchased direct from Gledhill to ensure compatibility/ continued safe operation.

Free of charge replacements for any faulty components are available from Gledhill during the in-warranty period (normally 12 months).

However, if any component is damaged during installation a new replacement must be ordered and paid for.

After th